StockSteel

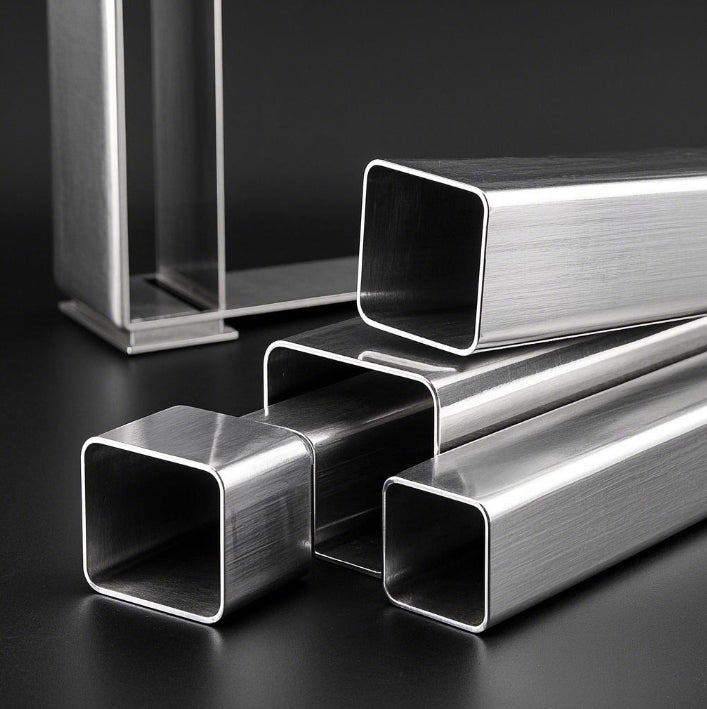

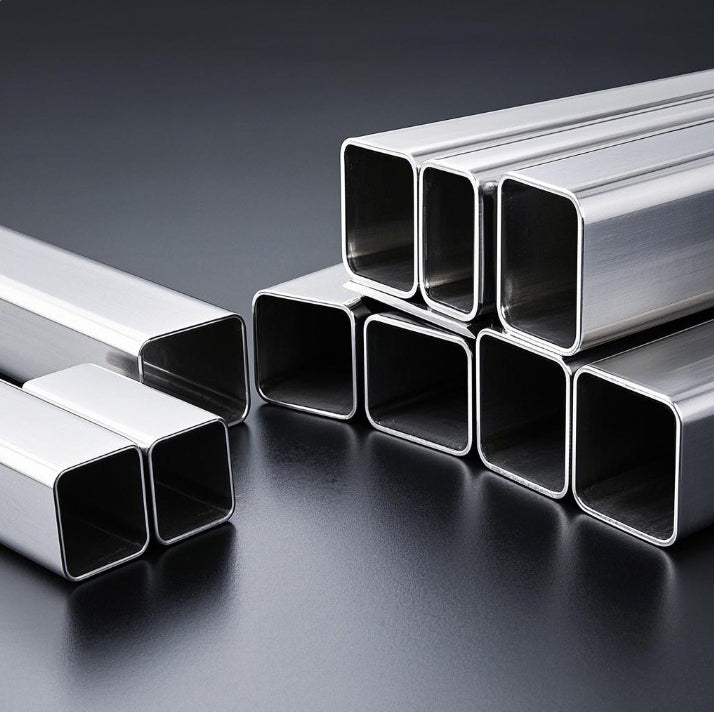

Premium Stainless Steel Pipe Tube | Hot-Rolled 304 & 904L Deals

Premium Stainless Steel Pipe Tube | Hot-Rolled 304 & 904L Deals

Couldn't load pickup availability

Premium Stainless Steel Pipe Tube | Hot-Rolled 304 & 904L Deals

Product Overview

Our stainless steel pipe tube solutions are engineered for industrial excellence, combining corrosion resistance, high-temperature durability, and cost-effectiveness. Designed for applications in oil/gas, construction, marine, and chemical industries, these pipes comply with ASTM, ASME, and ISO standards. The stainless steel 304L pipes & tubes variant offers enhanced weldability and low-carbon properties, while the 904L grade excels in extreme environments.

Technical Specifications

Key Attributes & Dimensions

| Attribute | Details |

|---|---|

| Material Grades | 304, 304L, 316L, 904L (ASTM A312, A269, A106) |

| Outer Diameter (OD) | 13.7mm – 813mm (seamless) / 21.3mm – 508mm (welded) |

| Thickness | 1.2mm – 60mm (Sch5-Sch80) |

| Hardness | HRB 80–90 (304L), HRB 85–95 (904L) |

| Surface Finish | Polished, hot-rolled, galvanized, or customized |

| Length | 6m–12m (standard) / Custom-cut available |

| Packaging | Hexagonal bundles, wooden cases, PVC sleeves, waterproof paper |

Performance Characteristics

1. Tensile & Bend Strength

- Tensile Strength:

- 304L: 485–620 MPa | 904L: 490–690 MPa.

- Superior resistance to stress corrosion cracking, ideal for high-pressure pipelines.

- Bend Strength:

- 304L maintains ductility even at subzero temperatures (-196°C), while 904L withstands sulfuric acid environments.

2. Weight Calculation

Use the formula:

Weight (kg/m) = (OD – Thickness) × Thickness × 0.02491

Example: For a 50mm OD pipe with 2mm thickness:

(50 – 2) × 2 × 0.02491 = 2.35 kg/m

3. Rust Prevention

While stainless steel pipe tube is corrosion-resistant, improper handling or exposure to chlorides (e.g., seawater) can cause localized pitting. Regular passivation and avoiding contact with carbon steel tools mitigate this.

4. Identification & Marking

- Laser-etched labels include: Material Grade (e.g., 304L), Standard (ASTM/ASME), OD/Thickness, and Heat Number.

- Color-coded caps distinguish grades: Blue for 304L, Yellow for 904L.

Manufacturing Process

| Stage | Description |

|---|---|

| Hot Rolling | Heated billets shaped into pipes at 1100–1250°C for uniform grain structure. |

| Cold Drawing | Precision sizing for tight tolerance (±0.1mm). |

| Welding (Welded Tubes) | TIG or laser welding with argon shielding to prevent oxidation. |

| Heat Treatment | Solution annealing (1040–1120°C) to restore corrosion resistance. |

| Surface Treatment | Pickling, polishing, or galvanizing per application needs. |

Why Choose Our Stainless Steel Pipe Tubes?

Competitive Pricing & Bulk Offers

Access our stainless steel pipe tube pricelist with volume discounts:

- 304L: 1,500/ton (MOQ 1 ton).

- 904L: 2,800/ton (MOQ 5 tons).

Custom quotes available for projects exceeding 100 tons.

Certifications & Compliance

- ISO 9001, API 5L, BV, SGS, and ASME-certified production.

- Traceable material test reports (MTRs) for every batch.

Applications

- Oil/Gas: High-pressure pipelines, casing tubes.

- Food & Pharma: Sanitary welded pipes with electropolished surfaces.

- Construction: Structural support beams, heat exchangers.

Why Choose Us?

- 25+ Years of Expertise: Partner with Tianjin Ruijie Steel Pipe Ltd.—a leader in North China’s steel industry.

- Fast Delivery: 5–7 days for standard sizes; 25 days for custom orders.

- Global Logistics: FOB services from Xingang/Shanghai ports.

- Technical Support: Free consultation on material selection and fabrication.

- Sustainability: Recyclable packaging and eco-friendly production.