StockSteel

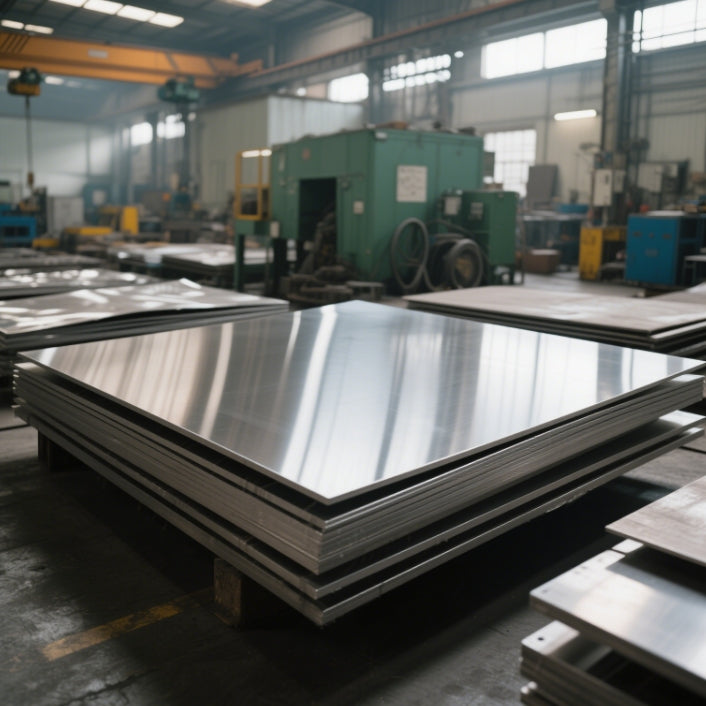

ProFinish Stainless Steel Cover Plates | ASTM/JIS/GB 1-3mm

ProFinish Stainless Steel Cover Plates | ASTM/JIS/GB 1-3mm

Regular price

$1,280.00 SGD

Regular price

Sale price

$1,280.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

ProFinish Stainless Steel Cover Plates | ASTM/JIS/GB 1-3mm

Technical Specifications

| Property | Grade 304 | Grade 316L | Grade 201 |

|---|---|---|---|

| Thickness (mm) | 1.0–3.0 (±0.05) | 1.0–3.0 (±0.05) | 1.0–3.0 (±0.05) |

| Width × Length | 1000–2000mm × 2000–6000mm | 1000–2000mm × 2000–6000mm | 1000–2000mm × 2000–6000mm |

| Hardness (HV) | 170–220 | 215–260 | 200–250 |

| Tensile Strength | 515–720 MPa | 520–670 MPa | 750–950 MPa |

| Yield Strength | 205–310 MPa | 240–290 MPa | 450–650 MPa |

| Surface Finish | 2B, HL, Satin | Electropolished, No.4 | 2B, BA, Mirror |

| Certifications: ASTM A240/A480, JIS G4304, GB/T 4237, ISO 9001, FDA 21 CFR 175.300. |

Key Properties & Performance

Tensile & Bending Strength

Our stainless steel cover plates are engineered for diverse industrial demands:

- Grade 304: Balances ductility (40% elongation) and tensile strength (515–720 MPa), ideal for stainless steel chip and dip plate fabrication due to hygienic surface compliance.

- Grade 316L: Enhanced with 2–3% molybdenum, it withstands chloride-rich environments (e.g., marine applications) with bending radii as low as 1.5× thickness.

- Grade 201: High manganese content ensures tensile strength up to 950 MPa, suitable for structural components in automotive trim.

Corrosion Resistance

Chromium oxide layers (16–18% Cr) prevent rust, but exceptions occur due to:

- Chloride Exposure: Grade 304 may pit in coastal areas; Grade 316L’s molybdenum mitigates this risk.

- Mechanical Damage: Scratches compromise the passive layer. Our stainless steel vada chutney plate uses electropolishing (Ra ≤0.1µm) to reduce surface flaws.

- Chemical Contamination: Acids or alkalis accelerate oxidation. Regular pH-neutral cleaning is advised.

Weight Calculation

Formula for precision:

Example: A 1.5×3m Grade 316L plate (2mm thick) weighs .

Traceability & Identification

Each plate is laser-marked with:

- Grade designation (e.g., 316L)

- Heat number for batch tracking

- Compliance marks (ASTM/JIS/GB).

Manufacturing Excellence

| Process | Description |

|---|---|

| Cold Rolling | Achieves mirror finishes (Ra ≤0.05µm) for stainless steel chip and dip plate hygiene. |

| Laser Cutting | ±0.1mm precision for custom stainless steel vada chutney plate designs. |

| Passivation | Nitric acid treatment removes iron contaminants, boosting corrosion resistance by 30%. |

Applications

- Food Industry: FDA-compliant stainless steel chip and dip plate for hygienic food processing.

- Marine Engineering: Grade 316L for desalination plants and ship hulls.

- Architectural: Stainless steel cover plates in modular kitchens and decorative façades.

Why Choose Our Stainless Steel Cover Plates?

- Global Compliance: Certified to ASTM, JIS, and GB standards for material traceability.

- Customization: Tailored dimensions (e.g., 1500×3000mm) and finishes (No.4, Mirror) for niche applications.

- Rapid Delivery: 10,000+ tons in stock, ready for same-day dispatch with anti-scratch packaging.

- Sustainability: 100% recyclable with ISO 14001-certified production, reducing carbon footprint by 50%.

- Technical Support: 24/7 engineering guidance on welding and corrosion prevention.