StockSteel

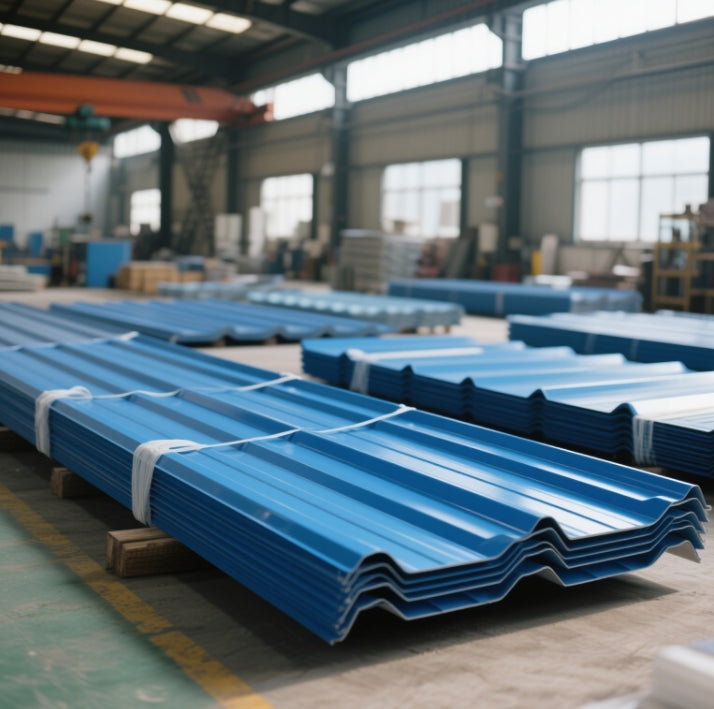

Proven Tin Roofing Sheets | High-Quality SGCC Material

Proven Tin Roofing Sheets | High-Quality SGCC Material

Couldn't load pickup availability

Proven Tin Roofing Sheets | High-Quality SGCC Material

Product Specifications

| Attribute | Details |

|---|---|

| Material | SGCC (Hot-Dip Galvanized Steel) with 55% aluminum-zinc alloy coating |

| Thickness | 0.12–1.5 mm (customizable up to 2.28 mm for heavy-duty applications) |

| Width | 600–1250 mm (standard), customizable upon request |

| Coating Weight | 30–275 g/m² (adjustable for corrosion resistance needs) |

| Surface Finish | Chromated, Oiled, Anti-Fingerprint (AFP), or Matte |

| Hardness (Temper) | T1–T5, DR7–DR9, HRB 45–85 (optimized for structural and roofing uses) |

| Tensile Strength | 260–620 MPa (complies with ASTM A653 and JIS G3302 standards) |

| Certifications | ISO 9001, SGS, KS D3506, RoHS |

Key Properties & Performance

1. Tensile & Flexural Strength

Our metal sheet roof products are engineered for exceptional durability. The tensile strength ranges from 260–620 MPa, depending on the SGCC grade and tempering process. This ensures resistance to deformation under heavy loads, such as snow accumulation or wind pressure up to 150 mph. Flexural strength is enhanced by the cold-rolled manufacturing technique, allowing bending angles up to 180° without cracking—ideal for complex sheet metal for roofing designs.

2. Weight Calculation

Calculate sheet weight using the formula:

For example, a 1m × 1m sheet with 0.5mm thickness weighs 3.925 kg. Custom widths and lengths are available to minimize material waste.

3. Marking System

Each roofing metal sheets is laser-marked with:

- Material Grade (e.g., SGCC, DX51D)

- Coating Type (e.g., Z275 for 275 g/m² zinc-aluminum coating)

- Certification Codes (ISO, KS, or ASTM compliance)

This ensures traceability and adherence to international quality standards.

4. Why SGCC Sheets Resist Rust

While sheet metal for roofing products are designed for corrosion resistance, understanding rust mechanisms is critical:

- Sacrificial Protection: The zinc-aluminum coating acts as a sacrificial anode, corroding preferentially to protect the underlying steel.

- Barrier Protection: The dense oxide layer formed by aluminum (55%) blocks oxygen and moisture diffusion.

- Galvanic Compatibility: Unlike pure zinc, the alloy coating minimizes electrochemical reactions with contaminants like salt or acid rain.

- UV Stability: Reflective surfaces reduce thermal expansion stress, preventing micro-cracks that could expose the base metal.

Why Choose Our SGCC Roofing Sheets?

- Superior Corrosion Resistance: Tested for 1,000+ hours in salt spray (ASTM B117), outperforming traditional galvanized sheets.

- Cost Efficiency: Metal sheet roof options start at $2.8/m² (bulk orders), offering a 50-year lifespan—3x longer than asphalt shingles.

- Eco-Friendly: 100% recyclable with 40% lower carbon emissions compared to conventional roofing.

- Customization: Tailored dimensions, spangle patterns (zero, regular, or minimal), and hardness grades (soft to full-hard).

- Global Compliance: Certified by Korean KS, EU EN 10142, and ASTM standards, ensuring acceptance in 100+ countries.

Why Our SGCC Sheets Stand Out

- Zero Defect Assurance: Every batch undergoes third-party SGS/BV inspections and destructive testing.

- Logistics Excellence: As a Class-A agent for MSC/MSK/COSCO, we guarantee 15-day delivery and real-time shipment tracking.

- OEM/ODM Support: Free logo stamping, custom packaging, and technical drawings for architectural projects.

- Lifetime Warranty: 10-year material guarantee with 24/7 engineering support.

For quotes or samples, contact us today! 🌟