StockSteel

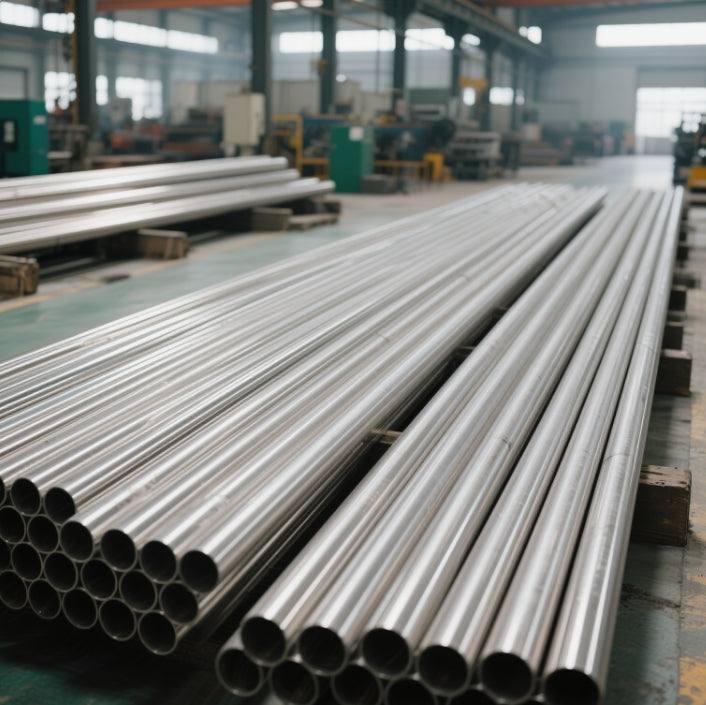

Robust Carbon Steel Pipe Solutions | Certified & Durable

Robust Carbon Steel Pipe Solutions | Certified & Durable

Couldn't load pickup availability

Robust Carbon Steel Pipe Solutions | Certified & Durable

Product Specifications

| Parameter | Details |

|---|---|

| Standard | ASTM A572 Grade 50, ASTM A53, API 5L, EN 10219 |

| Hardness | 167-228 HB (Brinell), varies with carbon content (low to high carbon)

1

|

| Sizes | - OD: 0.5" to 48" (seamless), 4" to 100" (welded) |

| - Wall Thickness: 0.035" to 2.0" | |

| - Length: 20 ft (standard), up to 40 ft (customizable) | |

| Material Properties | - Carbon: 0.05%-2.1% |

| - Manganese: 1.35% max | |

| - Yield Strength: ≥50 ksi (345 MPa) | |

| - Elongation: 21% min | |

| Processing | Hot-rolled, cold-drawn, ERW (Electric Resistance Welded), galvanized |

Technical Details

1. Tensile Strength

Carbon steel pipe exhibits exceptional tensile strength, ranging from 360 MPa (low carbon) to ≥520 MPa (high carbon). This property ensures structural integrity under high-pressure conditions, making it ideal for oil and gas pipelines, construction frameworks, and heavy machinery. The tensile strength is directly influenced by carbon content and heat treatment processes, such as quenching and tempering.

2. Bending Strength

The bending resistance of carbon steel pipe is closely tied to its ductility and wall thickness. For example, Grade 50 pipes can withstand bending angles of up to 90° without cracking when cold-formed, thanks to their balanced manganese and silicon content. This makes them suitable for applications requiring complex geometries, such as handrails and automotive exhaust systems.

3. Identification Methods

- Marking: ASTM-compliant pipes are stamped with grade (e.g., A572), heat number, size, and manufacturer’s logo.

- Testing: Third-party certifications (e.g., ISO 9001) validate chemical composition and mechanical properties via spectroscopy and tensile tests.

4. Weight Calculation Formula

The theoretical weight of carbon steel pipe is calculated as:

Weight (kg/m) = (OD - Wall Thickness) × Wall Thickness × 0.02466

For instance, a 6" SCH 40 pipe (OD 168.3mm, WT 7.11mm) weighs approximately 28.41 kg/m.

5. Why Does Stainless Steel Rust?

Despite its name, stainless steel can corrode under specific conditions:

- Chloride Exposure: Coastal environments or de-icing salts degrade the chromium oxide layer.

- Surface Contamination: Iron particles from tools or grinding can initiate localized rusting.

- Mechanical Damage: Scratches or dents expose the base metal to oxidation.

Regular cleaning and passivation can mitigate these risks.

Why Choose Our Stainless Steel Solutions?

- Superior Corrosion Resistance: Our carbon steel pipe fittings are coated with zinc or epoxy for enhanced durability, while stainless steel options use 304/316L grades with 18% chromium and 8% nickel.

- Customized Processing: Laser cutting, CNC bending, and precision welding ensure seamless integration with carbon fiber pipe systems.

- Certified Quality: All products undergo rigorous inspection by ISO-certified labs, guaranteeing compliance with ASTM, EN, and API standards.

- Eco-Friendly: Zero formaldehyde emissions and 100% recyclable material align with green manufacturing principles.