StockSteel

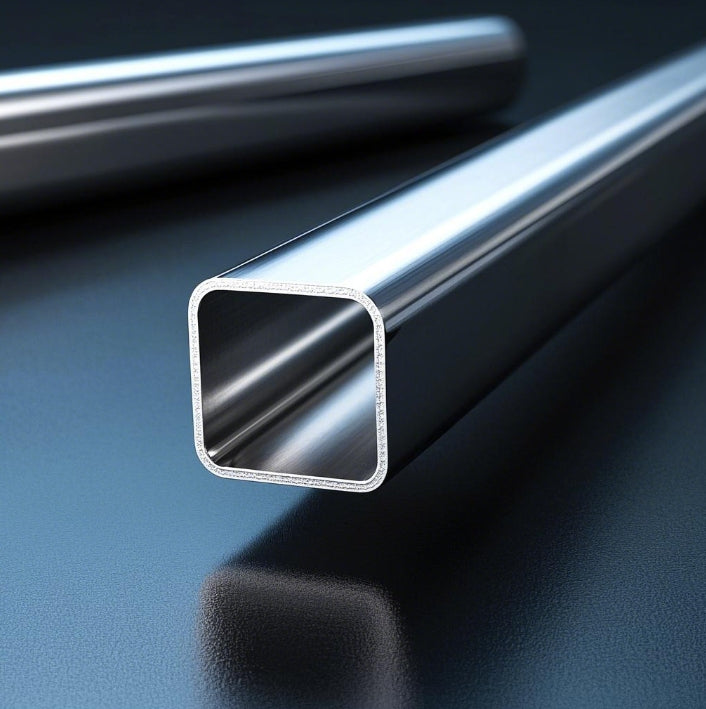

Robust Stainless Steel Tube Pipe | 304 Industrial Grade

Robust Stainless Steel Tube Pipe | 304 Industrial Grade

Couldn't load pickup availability

Robust Stainless Steel Tube Pipe | 304 Industrial Grade

Product Overview

Our stainless steel tube pipe is engineered for industrial applications requiring exceptional durability and corrosion resistance. Manufactured from premium 304-grade stainless steel, this product excels in harsh environments, including chemical processing, oil and gas systems, and structural frameworks. Available in corrugated stainless steel tube gas pipe designs for enhanced flexibility and cost-effective stainless steel pipes and tubes solutions, our inventory meets ASTM, DIN, and JIS standards, ensuring compliance with global quality benchmarks.

Technical Specifications

| Attribute | Details |

|---|---|

| Material Grade | 304, 304L, 316, 316L (AISI/EN/DIN/JIS compliant) |

| Dimensions | OD: 6–2500 mm; Thickness: 0.3–50 mm; Length: 1–12 m (customizable) |

| Surface Finish | Polished (Ra ≤0.4μm), Pickled, Annealed, or Corrugated |

| Hardness (Rockwell B) | 70–90 HRB (Annealed); Up to 201 HB (Cold Worked) |

| Processing | Seamless (Hot/Cold Rolled), Welded, Electro-polished |

| Standards | ASTM A312, A269, A358; DIN 17456; JIS G3459 |

Mechanical Properties

-

Tensile Strength:

- 304 Stainless Steel: Minimum 515 MPa (74,700 psi).

- Cold-Worked Variants: Up to 860 MPa (124,700 psi) for high-pressure applications like corrugated stainless steel tube gas pipe systems.

- This ensures structural integrity in load-bearing frameworks and fluid transport under extreme conditions.

-

Bending Strength:

- Achieves 1.5× tensile strength (≈773 MPa) due to the austenitic microstructure.

- Ideal for applications requiring tight-radius bends, such as HVAC ducting and machinery components.

Identification & Marking Methods

- Laser Etching: Permanent grade markings (e.g., "304," "316L") for traceability.

- Color Coding: PVC sleeves or painted ends to differentiate stainless steel tube pipe sizes and grades.

- Certification Tags: Mill Test Reports (MTR) with chemical composition and mechanical data.

Weight Calculation Formula

For cost-effective stainless steel pipes and tubes, weight per meter is calculated as:

Where:

- = Outer Diameter (mm)

-

= Wall Thickness (mm)

Example: A 100×100 mm square tube with 5 mm thickness weighs ≈11.8 kg/m.

Why Stainless Steel Rusts?

Despite its corrosion resistance, stainless steel can rust under specific conditions:

- Chloride Exposure: Chlorine ions in seawater or cleaning agents penetrate the chromium oxide layer, causing pitting corrosion.

- Mechanical Damage: Scratches or abrasions expose the iron-rich substrate to oxygen, initiating oxidation.

- Low Oxygen Environments: In stagnant water or enclosed spaces, the passive film cannot self-repair.

- Galvanic Corrosion: Contact with carbon steel or copper accelerates rusting in humid conditions.

Our 304-grade tubes mitigate these risks with 18–20% chromium and 8–10.5% nickel, ensuring robust passivation and self-healing properties.

Why Choose Our Stainless Steel?

- Certified Quality: Compliant with ASTM, DIN, and JIS standards for guaranteed performance.

- Custom Sizes: Tailor-made stainless steel tube pipe dimensions to fit unique project needs.

- Bulk Savings: Cost-effective stainless steel pipes and tubes with volume discounts and fast global shipping.

- Versatility: Suitable for corrugated stainless steel tube gas pipe systems, structural frameworks, and sanitary applications.

- Low Maintenance: Non-porous surfaces reduce cleaning costs and bacterial growth.