StockSteel

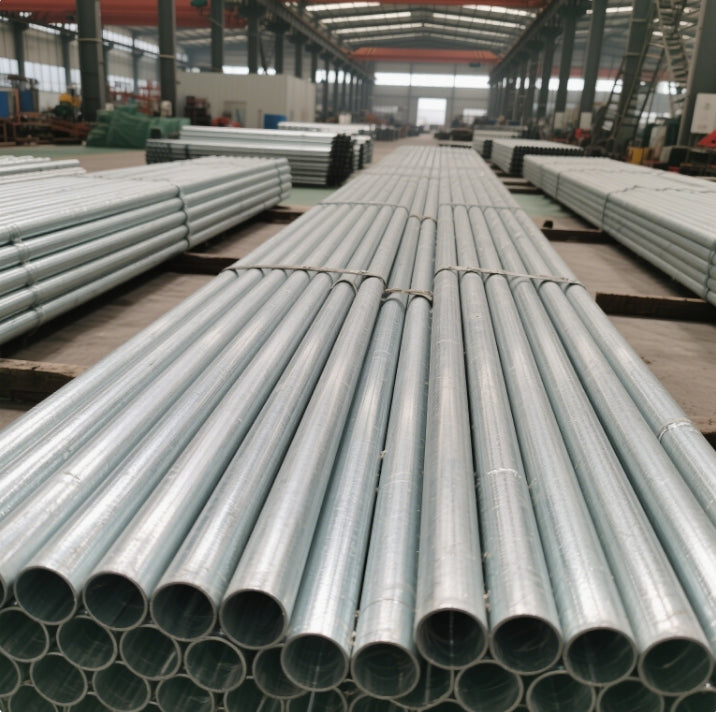

Rust-Proof galvanized pipe fittings | Hot-Dip Coated for Water Systems

Rust-Proof galvanized pipe fittings | Hot-Dip Coated for Water Systems

Couldn't load pickup availability

Rust-Proof Galvanized Pipe Fittings | Hot-Dip Coated for Water Systems

Product Specifications

| Attribute | Details |

|---|---|

| Material | Hot-dip galvanized steel (ASTM A53/A123, ASTM A153) with 60–275 g/m² zinc coating |

| Standards | ASTM A53, BS 1387, ISO 1461, EN 10240 |

| Diameter Range | ½" (15 mm) – 12" (300 mm) |

| Wall Thickness | 0.6 mm – 6.0 mm (customizable for cut galvanized steel pipe applications) |

| Zinc Coating Method | Hot-dip galvanizing (HDG) |

| Tensile Strength | 330–480 MPa (ASTM A53 Grade B) |

| Hardness | 70–80 HRB (Rockwell B) |

| Surface Finish | Smooth, spangle-free zinc layer with optional PVC/PE coating |

| Connection Type | Threaded (NPT/BSPT), welded, or grooved for fitting galvanized pipe |

Mechanical Properties & Performance

Tensile & Bend Strength

Our black galvanized steel pipe achieves a tensile strength of 330–480 MPa, ideal for high-pressure water systems and structural applications. The hot-dip zinc coating enhances fatigue resistance, preventing cracks even under dynamic loads (e.g., water hammer in pipelines). For bend strength, the yield strength of 210–310 MPa allows cold-forming without flaking, ensuring durability in curved installations like irrigation pivots.

Weight Calculation

Use the formula:

Example: For a 48.3 mm OD pipe with 2.0 mm wall thickness:

Identification & Marking

Each cut galvanized steel pipe is stamped with:

- Manufacturer’s logo and batch number for traceability.

- Grade (e.g., Q235, ASTM A53) and standard code.

- Fitting galvanized pipe dimensions (OD, wall thickness) and coating type.

Why Stainless Steel Can Rust & How Galvanized Pipes Prevent It

While stainless steel resists rust via chromium oxide layers, chloride exposure (e.g., seawater, road salts) or mechanical damage can breach this protective layer, leading to pitting corrosion. In contrast, hot-dip galvanized pipe fittings use sacrificial zinc coating:

- Barrier Protection: Zinc isolates steel from moisture and oxygen.

- Cathodic Protection: Zinc corrodes preferentially, shielding the base metal even if scratched.

- Longevity: HDG coating lasts 20–50 years in water systems, outperforming standard stainless steel in chloride-rich environments.

Applications in Water Systems

| Use Case | Benefits |

|---|---|

| Potable Water Lines | Smooth interior minimizes scaling; zinc coating prevents biofilm formation. |

| Fire Suppression | High-pressure resistance ensures reliability in emergency systems. |

| Industrial Plumbing | Fitting galvanized pipe resists chemical corrosion in acidic/alkaline fluids. |

| Agricultural Irrigation | Cut galvanized steel pipe withstands UV exposure and soil abrasion. |

Why Choose Our Stainless Steel Solutions?

While black galvanized steel pipe excels in water systems, our stainless steel products offer unmatched hygiene and longevity for specialized scenarios:

- AISI 304/316L: Resists chloride-induced pitting in marine environments.

- Hygienic Design: Smooth surfaces meet FDA/NSF standards for food-grade applications.

- Zero Maintenance: No recoating required, reducing lifecycle costs by 30%.