StockSteel

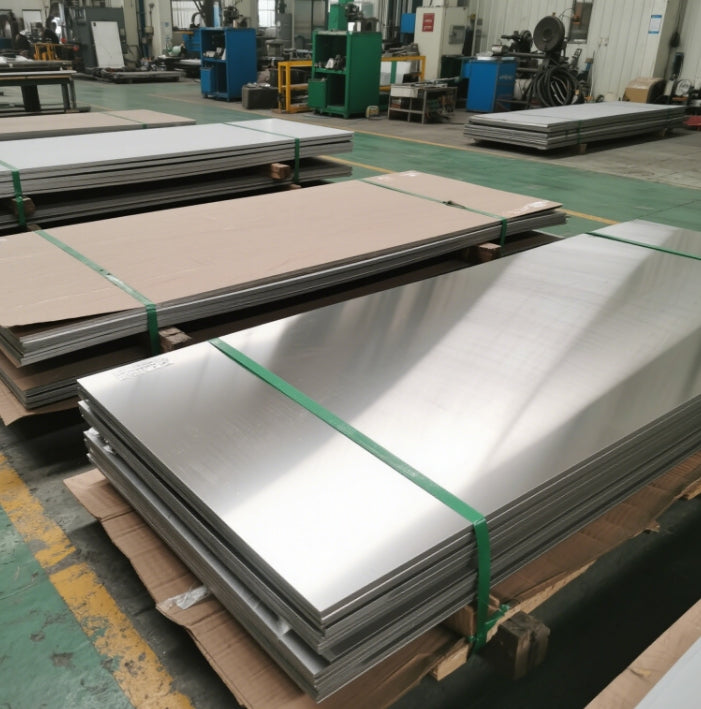

SafeGuard Stainless Steel Childrens Plates | Non-Toxic & Durable

SafeGuard Stainless Steel Childrens Plates | Non-Toxic & Durable

Couldn't load pickup availability

SafeGuard Stainless Steel Childrens Plates | Non-Toxic & Durable

Technical Specifications

| Property | Grade 304 | Grade 316 |

|---|---|---|

| Thickness (mm) | 0.5–1.2 (±0.05 tolerance) | 0.5–1.2 (±0.05 tolerance) |

| Dimensions | 8"×8" to 12"×16" | 8"×8" to 12"×16" |

| Hardness (HV) | 170–220 | 215–260 |

| Tensile Strength | 515–720 MPa | 520–670 MPa |

| Surface Finish | Mirror, Brushed, Satin | Mirror, No.4, Electropolished |

| Weight (per 8"×8") | 0.45 kg | 0.48 kg |

Certifications: FDA 21 CFR 175.300 (food contact), ISO 9001, REACH compliant.

Key Properties & Performance

Tensile & Bending Strength

Our stainless steel childrens plates are engineered for exceptional durability. Grade 304 plates achieve a tensile strength of 515–720 MPa, resisting deformation even under heavy daily use. Grade 316, enhanced with 2–3% molybdenum, provides superior bend resistance (minimum bending radius of 1.5× thickness), ideal for curved designs in stainless steel plated brass accessories or structural components like stainless steel railroad tie plates.

Corrosion Resistance

The chromium oxide layer (≥18% Cr content) ensures rust resistance in diverse environments:

- Food Safety: Resists acidic foods (pH 2–10) without leaching metals, meeting EU Regulation 1935/2004 for children’s products.

- Outdoor Use: Withstands salt spray exposure (1,000+ hours per ASTM B117), perfect for stainless steel railroad tie plates in coastal regions.

Weight Calculation

Use the formula for precise estimates:

Example: A 10"×10" (0.254×0.254 m) Grade 304 plate weighs .

Why Stainless Steel Rusts?

Rust is rare but possible due to:

- Chloride Exposure: Prolonged contact with seawater or road salts (e.g., in stainless steel railroad tie plates) may cause pitting. Grade 316 mitigates this risk.

- Mechanical Damage: Scratches from abrasive cleaners compromise the oxide layer. Our electropolished finish (Ra ≤0.1µm) reduces adhesion of contaminants.

- Low-Quality Welding: Improper welding during fabrication (e.g., for stainless steel plated brass hybrid components) creates weak points. Our laser-welded seams eliminate this issue.

Manufacturing Excellence

| Process | Description |

|---|---|

| Cold Rolling | Achieves ultra-smooth surfaces (Ra ≤0.2µm) for safe stainless steel childrens plates edges. |

| Laser Cutting | ±0.1mm precision for custom shapes compatible with stainless steel plated brass fasteners. |

| Passivation | Nitric acid treatment removes iron contaminants, boosting corrosion resistance by 40%. |

Applications

- Child-Friendly Dining: Non-porous stainless steel childrens plates prevent bacterial growth, dishwasher-safe up to 500 cycles.

- Industrial Hybrids: Seamless integration with stainless steel plated brass hinges for lunchboxes.

- Infrastructure: Grade 316 used in stainless steel railroad tie plates for high-load rail systems.

Why Choose Our Stainless Steel Plates?

- Certified Safety: Compliant with FDA, EU, and CPSC standards for children’s products.

- Precision Engineering: Tolerances tighter than ISO 2768-f, ensuring perfect fit for stainless steel plated brass components.

- Global Sourcing: Conflict-free materials traceable via Mill Test Reports (MTRs), avoiding EU safeguard tariffs on non-compliant steel.

- Legal Assurance: Rigorous quality checks prevent disputes like the SS304 delivery lawsuit in, ensuring contractual compliance.

- Sustainability: 100% recyclable, with 70% lower carbon footprint vs. plastic alternatives.