StockSteel

Safety-First plate stainless steel | Non-Slip Elevator Shaft Flooring

Safety-First plate stainless steel | Non-Slip Elevator Shaft Flooring

Couldn't load pickup availability

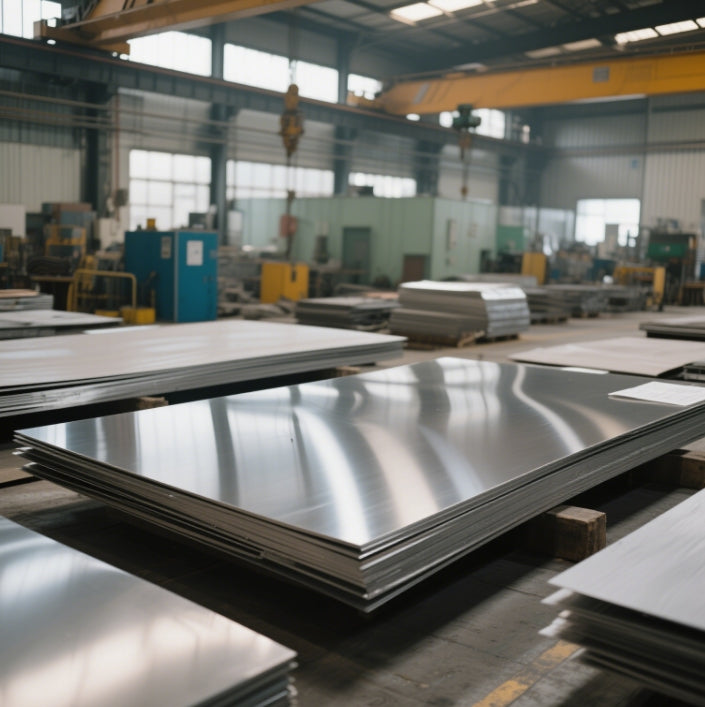

Safety-First Stainless Steel Plate | Non-Slip Elevator Shaft Flooring

Product Overview

Our safety-first stainless steel plates are engineered to deliver unmatched durability and slip resistance for high-risk environments like elevator shafts, industrial platforms, and public staircases. Featuring stainless steel checkered plate designs with anti-slip diamond or lentil patterns, these plates combine ASTM-certified strength with corrosion resistance. Ideal for stainless steel door kick plate installations or decorative accents like stainless steel gold plated bracelet trims, they ensure safety without compromising aesthetics.

Specifications & Properties

| Property | Details |

|---|---|

| Material | 304, 316L stainless steel (70% recycled content, food-grade options available) |

| Thickness | 1.5mm–30mm (standard stainless steel checkered plate at 3–6mm for elevator flooring) |

| Width | 500mm–2500mm (customizable for elevator shafts or stainless steel door kick plate panels) |

| Length | 1m–6m (standard or custom lengths) |

| Surface Finish | Embossed (anti-slip), Brushed, PVD Coated (e.g., stainless steel gold plated bracelet-style finishes) |

| Hardness | 304: HRB 70–88; 316L: HRB 75–95 (scratch-resistant for heavy traffic) |

| Certifications | ASTM E84, ISO 5660, LEED, GB 8624 (Class A1 Fire Rating) |

| Processing | Laser Cutting, Cold Rolling, Electro-Polishing, Thermal Spraying |

Key Features

1. Tensile & Bend Strength

- Tensile Strength: Ranges from 515 MPa (304 grade) to 620 MPa (316L), ensuring structural integrity under extreme loads in elevator shafts or industrial walkways. Cold-rolled variants achieve higher yield strength (up to 310 MPa), minimizing deformation under dynamic stress.

- Bend Strength: Engineered to resist warping even at sub-zero temperatures, critical for curved stainless steel door kick plate installations or outdoor staircases.

2. Identification & Weight Calculation

- Identification: Grades are laser-etched per ASTM/EN standards (e.g., "316L") with traceability codes for safety audits.

- Weight Formula:Example: A 3mm × 1m × 2m stainless steel checkered plate weighs 47.58 kg.

3. Corrosion Resistance & Rust Prevention

Stainless steel’s chromium oxide layer (≥10.5% Cr) provides inherent corrosion resistance. However, localized rust may occur due to:

- Chloride Exposure: Coastal environments or de-icing salts accelerate pitting. Our 316L grade includes 2-3% molybdenum for enhanced chloride resistance.

- Mechanical Damage: Scratches from abrasive tools compromise the oxide layer. Electro-polishing restores surface integrity, ideal for stainless steel gold plated bracelet-like finishes.

- Galvanic Corrosion: Direct contact with carbon steel triggers electrochemical reactions. Insulating gaskets are recommended for mixed-material installations.

Applications

- Elevator Safety: Anti-slip stainless steel checkered plate flooring with diamond patterns for secure footing.

- Architectural Protection: Durable stainless steel door kick plate panels to shield high-traffic entrances.

- Decorative Accents: Luxury stainless steel gold plated bracelet-style trims for architectural façades.

Why Choose Our Stainless Steel Plates?

- Safety-Certified: Compliant with ASTM E84 fire resistance (6+ hours) and ISO 5660 slip resistance standards.

- Customization: Tailored thicknesses, PVD coatings (e.g., gold, black), and embossed patterns for unique projects.

- Eco-Conscious: 70% recycled content and low-energy manufacturing align with LEED sustainability criteria.

- Global Logistics: Bulk orders shipped within 15–30 days; prototypes available in 5–7 days.

- Lifetime Warranty: 10-year quality guarantee against corrosion and structural defects.