StockSteel

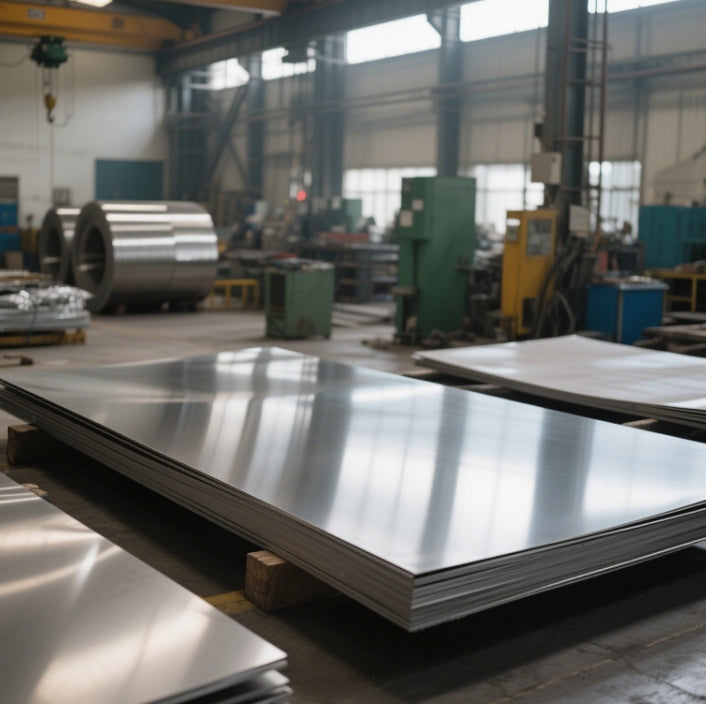

Slip-Resistant plate stainless steel | Elevator Flooring & Industrial Walkways

Slip-Resistant plate stainless steel | Elevator Flooring & Industrial Walkways

Regular price

$1,460.00 SGD

Regular price

Sale price

$1,460.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

Slip-Resistant Stainless Steel Plate

Elevator Flooring & Industrial Walkways

Technical Specifications

| Property | Details |

|---|---|

| Material Grade | 304 / 316L / 2205 Duplex |

| Thickness Range | 0.5mm – 100mm (Cold Rolled: 0.5–6mm; Hot Rolled: 4–100mm) |

| Width | 1000mm – 1500mm (Customizable up to 2500mm) |

| Length | 2000mm – 6500mm (Standard); Custom Cut-to-Size Available |

| Surface Finish | No.4 Brushed, HL Hairline, Embossed, Diamond Plate, Powder-Coated |

| Hardness | ≤201 HBW (304); 210–310 HV (2205 Duplex); HRB 92 (304) |

| Slip Resistance | R13–R16 (DIN 51130); Customizable Embossed Patterns for High Traction |

| Edge Treatment | Laser-Cut, Deburred, or Rolled Edges |

| Certifications | ASTM A240, EN 10088, JIS G4304, ISO 9001 |

Key Features

1. Tensile Strength & Bend Performance

- Tensile Strength:

- 304/316L: 520–720 MPa (Annealed); 860 MPa (Cold Worked)

- 2205 Duplex: 620–900 MPa (Superior to Carbon Steel)

- Custom Heat Treatment: Available for enhanced strength (e.g., 1/2H, 3/4H)

- Bending Strength:

- Bend radii as low as 1x thickness (304/316L)

- High ductility (≥40% elongation for 304), ideal for complex shapes.

2. Material Identification

- ASTM Standards: 304 (UNS S30400), 316L (UNS S31603), 2205 (UNS S32205)

- Laser Etching: Permanent grade markings (e.g., "304-SRS" for slip-resistant)

- Mill Test Reports: Traceable chemical composition & mechanical properties

3. Weight Calculation

- Formula: stainless steel plate weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (7.93 g/cm³)

- Example: 3mm × 1.2m × 2.4m plate = 3×1.2×2.4×7.93 = 68.6 kg

- Lightweight Options: Thin plates (0.5–2mm) for stainless steel plates for kids play areas

4. Corrosion Resistance & Maintenance

- Why Stainless Steel Rusts?

- Chloride Exposure: Coastal areas or de-icing salts damage the passive layer

- Mechanical Damage: Scratches or iron contamination (use passivation to restore)

- Low Chromium: Ensure Cr ≥16% (304/316L) or Cr ≥22% (2205) for optimal protection

- Preventive Measures:

- Regular cleaning with pH-neutral detergents.

- Electro-polishing (Ra ≤0.2μm) for hygienic surfaces.

Applications

- Elevator Flooring: Anti-slip diamond patterns for ADA compliance

- Industrial Walkways: Heavy-duty embossed surfaces (load capacity up to 5 tons/m²)

- Kids’ Safe Zones: Non-toxic, rounded-edge stainless steel plates with suction for playgrounds

- Marine & Chemical: 2205 duplex for seawater resistance

Why Choose Our Stainless Steel Plates?

- Precision Manufacturing:

- 6-roll cold milling (±0.01mm tolerance)

- Vacuum-arc remelted (VAR) steel for ultra-low impurities

- Custom Solutions:

- Suction Plates: Vacuum-sealed designs for medical/food industries

- Fire-rated options (up to 800°C)

- Global Compliance:

- CE, RoHS, and TUV-certified

- Eco-Friendly:

- 100% recyclable, lead-free coatings

- Lifetime Support:

- Free technical consultation & corrosion analysis.