StockSteel

Slip-Resistant stainless steel plate | Ideal for Flooring & Safety-Critical Areas

Slip-Resistant stainless steel plate | Ideal for Flooring & Safety-Critical Areas

Regular price

$498.00 SGD

Regular price

Sale price

$498.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

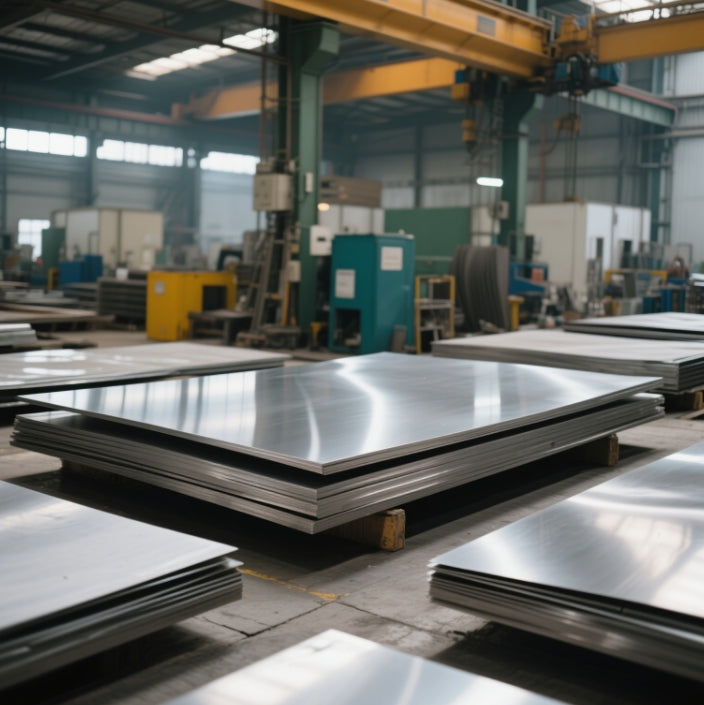

Slip-Resistant Stainless Steel Plate | Ideal for Flooring & Safety-Critical Areas

Product Overview

Our slip-resistant stainless steel plates are engineered to deliver unmatched safety and durability for high-traffic flooring, industrial walkways, and safety-critical environments. Featuring advanced anti-slip textures and corrosion-resistant alloys, these plates combine functionality with aesthetic versatility. Customizable to meet project-specific demands, they are ideal for commercial kitchens, marine platforms, and public infrastructure.

Specifications & Properties

| Property | Details |

|---|---|

| Material | 304, 316L, 430 stainless steel (optimized for slip resistance) |

| Thickness | 1.5mm–20mm (standard or custom) |

| Width | 600mm–2000mm (adjustable for stainless steel checker plate patterns) |

| Length | 1m–6m (custom lengths available) |

| Surface Finish | Embossed, Diamond Tread, PVD Coated, Brushed (texture options for anti-slip) |

| Hardness | 304: HRB 70–88; 316L: HRB 75–95; 430: HRB 80–95 |

| Certifications | ISO 9001, ASTM A240, EN 10088-2 |

| Processing | Laser Cutting, CNC Embossing, Hot Rolling, Electro-Polishing |

Key Features

1. Tensile & Bend Strength

- Tensile Strength: Ranges from 515 MPa (304 grade) to 620 MPa (316L), ensuring structural integrity under heavy loads and dynamic stress. This makes our plates ideal for industrial flooring and kenmore elite stainless steel 3 door 36 wide plate replacement applications, where resistance to deformation is critical.

- Bend Strength: Engineered to withstand repeated flexing without cracking, even in low-temperature environments. Cold-rolled processing enhances ductility, allowing for complex shapes in safety railings or machinery guards.

2. Identification & Weight Calculation

- Identification: Grades are laser-etched per ASTM/EN standards (e.g., "316L" for marine-grade steel). Traceability codes ensure compliance with safety regulations.

- Weight Formula:Example: A 3mm × 1m × 2m avanchy stainless steel plate weighs 47.58 kg (304 grade).

3. Corrosion Resistance & Rust Prevention

Stainless steel’s chromium content (≥10.5%) forms a self-repairing chromium oxide layer, blocking oxidation. However, localized rust may occur due to:

- Chloride Exposure: Coastal or de-icing salt environments accelerate pitting. Our 316L grade adds 2-3% molybdenum for enhanced chloride resistance.

- Mechanical Abrasion: Heavy foot traffic or equipment scraping can damage the oxide layer. Regular cleaning with pH-neutral detergents restores protection.

- Galvanic Corrosion: Avoid direct contact with carbon steel or copper. Insulating gaskets are recommended for mixed-material installations.

Applications

- Industrial Flooring: Anti-slip stainless steel checker plate for factories, oil rigs, and food processing plants.

- Architectural Safety: Stair treads, elevator floors, and rooftop walkways with PVD-coated finishes.

- Consumer Durables: Replacement parts like kenmore elite stainless steel 3 door 36 wide plate or hygienic avanchy stainless steel plate sets for commercial kitchens.

Why Choose Our Stainless Steel Plates?

- Anti-Slip Mastery: Custom embossed patterns (diamond, linen, or logo-specific textures) with a friction coefficient ≥0.5 (exceeding OSHA standards).

- Precision Engineering: Tolerances as tight as ±0.1mm for seamless integration into machinery or structural frameworks.

- Global Compliance: Meets ASTM, EN, and JIS certifications for fire resistance, load-bearing capacity, and hygiene.

- Eco-Conscious: 100% recyclable material with low lifecycle carbon footprint.

Why Us?

- Rigorous Quality Control: Each batch undergoes eddy current testing, salt spray trials (1,000+ hours), and load simulation.

- Fast Turnaround: Prototypes in 7 days; bulk orders shipped globally within 21 days.

- Cost Efficiency: Competitive pricing with volume discounts, reducing project overheads by up to 30%.

- Technical Support: 24/7 engineering assistance for texture selection, welding guidelines, and corrosion management.