StockSteel

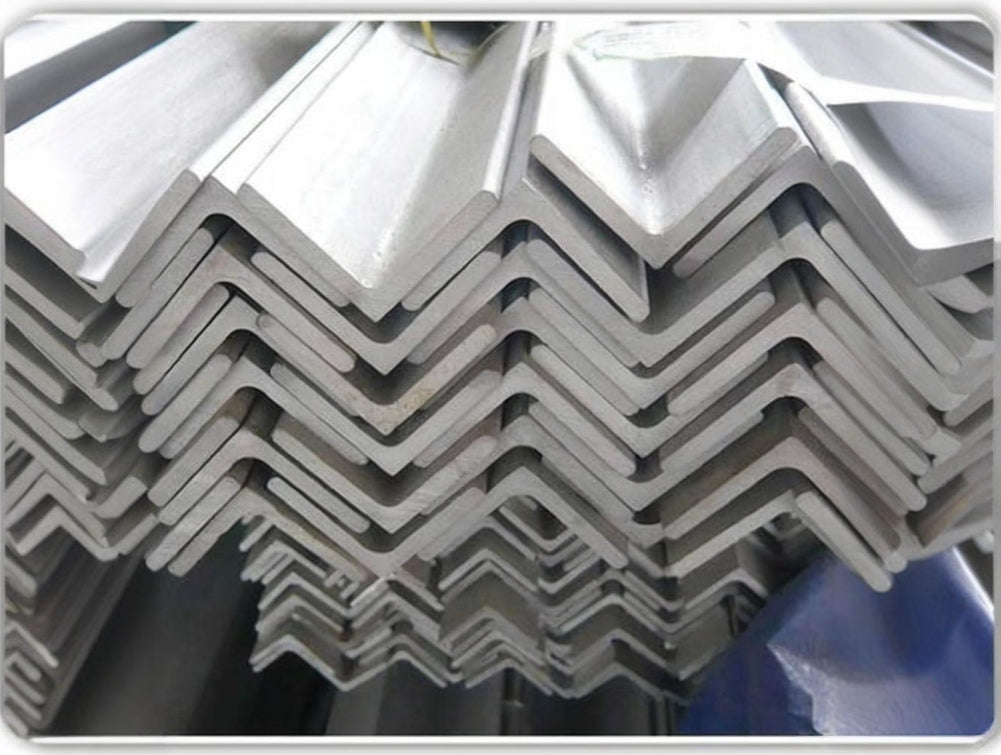

Stainless Steel Angle Brackets | Heavy-Duty Saltwater Defense

Stainless Steel Angle Brackets | Heavy-Duty Saltwater Defense

Couldn't load pickup availability

Stainless Steel Angle Brackets | Heavy-Duty Saltwater Defense

Product Specifications

| Property | Details |

|---|---|

| Material Standard | ASTM A554 (304/316L), EN 10088-3 (1.4301/1.4404), JIS SUS430/904L |

| Dimensions | Leg Length: 20–200 mm |

| Surface Finish | Polished (No.4/No.8), Bead Blasted, Passivated, or Electroplated (Optional) |

| Hardness (Rockwell B) | 304: ≤ 90 HRB |

| Yield Strength | 304: ≥ 205 MPa |

| Tensile Strength | 304: ≥ 515 MPa |

| Elongation | 304: ≥ 40% |

Key Attributes & Processing

| Category | Description |

|---|---|

| Chemical Composition | 304: 18% Cr, 8% Ni |

| Corrosion Resistance | 316L/904L grades resist pitting in chloride-rich environments (seawater, chemical plants) |

| Fabrication | Laser-cut slots, CNC-bent edges (±0.2 mm precision), TIG welding compatibility |

| Magnetic Properties | Austenitic grades (304/316L/904L) are non-magnetic; Ferritic (430) exhibits magnetism |

Performance Highlights

Tensile & Bending Strength

Stainless steel angle brackets made from Grade 316L achieve a tensile strength of ≥550 MPa, ideal for structural support in marine and coastal environments. Their high ductility (≥35% elongation) ensures resistance to deformation under dynamic loads, such as wave impacts or heavy machinery vibrations. For extreme chemical exposure, stainless steel angle braces in 904L alloy offer superior resistance to sulfuric acid and seawater corrosion, with tensile strength exceeding 490 MPa.

Identification & Marking

Each bracket is stamped or laser-etched with:

- Grade Markings (e.g., 304, 316L, 904L).

- Certification Codes (e.g., ASTM A554, EN 10088).

- Batch Numbers for full traceability (ISO 9001 compliance).

Weight Calculation

Calculate the weight of angle stainless steel brackets using:

Example: A 50×50×5 mm 304 bracket weighs .

Corrosion Resistance & Rust Prevention

While stainless steel angle brackets excel in harsh environments, rust risks arise from:

- Galvanic Corrosion: Direct contact with carbon steel or copper alloys in seawater. Insulate with nylon washers or coatings.

- Crevice Corrosion: Stagnant water in poorly designed slots. Opt for slotted stainless steel angle braces with rounded edges to improve drainage.

- Intergranular Attack: 430 grades exposed to 450–850°C may lose chromium. Use stabilized 316L/904L for welding applications.

Why Choose Our Stainless Steel Angle Brackets?

- Marine-Grade Expertise: We supply angle stainless steel in 304/316L/904L grades certified for shipbuilding (DNV/ABS/GL standards).

- Precision Engineering: CNC-machined slots and holes (±0.1 mm tolerance) ensure seamless integration into offshore platforms or desalination plants.

- Competitive Pricing: Factory-direct stainless steel angle braces with 15–30% cost savings over European suppliers.

- Fast Delivery: 10–20 days lead time for standard sizes; urgent orders shipped via DHL/FedEx.

- Custom Solutions: Tailor dimensions, finishes, and alloy grades for unique project needs, including slotted or galvanized variants.