StockSteel

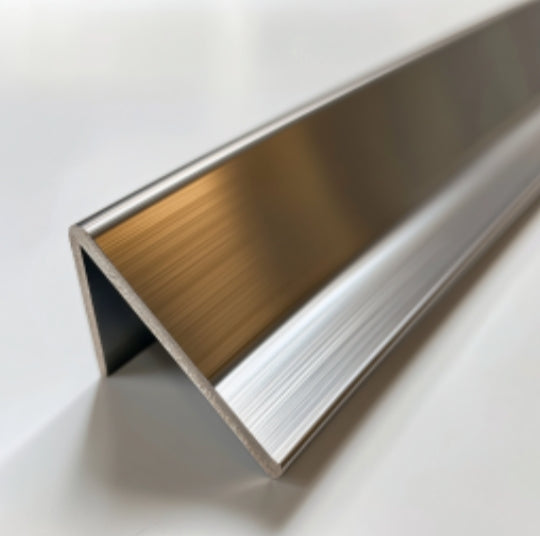

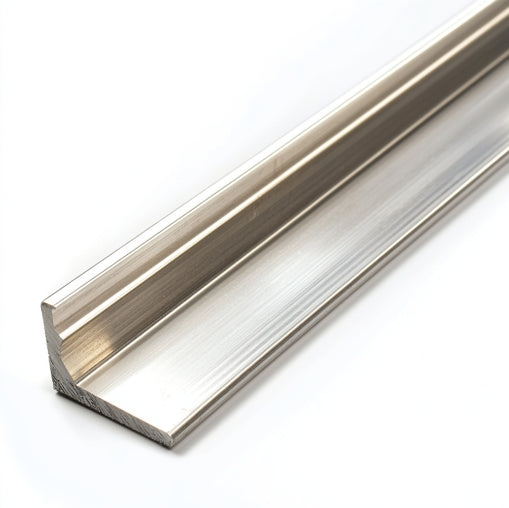

Stainless Steel Angle | Industrial Supplier & Custom Solutions

Stainless Steel Angle | Industrial Supplier & Custom Solutions

Couldn't load pickup availability

Stainless Steel Angle Product Details

Specifications, Hardness, Sizes, Properties & Manufacturing Process

| Category | Details |

|---|---|

| Material Grades | stainless steel angle iron: 201, 304/304L, 316/316L, 430, 2205 (Duplex) |

| Size Range | stainless steel angle brackets: 20×20×3mm – 200×200×20mm (L×W×T) Custom lengths up to 12m |

| Thickness | 1.5mm–25mm (±0.1mm tolerance for precision stainless steel angle trim) |

| Surface Finish | Bright Annealed, Polished (No.4/HL), Bead-Blasted, Satin |

| Hardness (HV) | • 304: 150–200 HV • 316L: 130–180 HV • Duplex 2205: 280–320 HV |

| Process Methods | Hot Rolled, Cold Drawn, Laser-Cut, TIG Welded, Precision Bent |

| Certifications | ASTM A554, EN 10088-3, ISO 9001, NACE MR0175 |

| Applications | Structural Frameworks (stainless steel angle brackets), Marine Edging (stainless steel angle trim), HVAC Ducting |

Key Performance Properties

Tensile Strength

Stainless steel angle iron grades like 304 and 316L exhibit tensile strengths of **≥520 MPa** and **≥485 MPa**, respectively, ensuring structural integrity in load-bearing applications such as industrial shelving and bridge supports. Duplex 2205 angles combine austenitic and ferritic phases, achieving **≥620 MPa tensile strength**, ideal for offshore platforms exposed to chloride-rich environments.

Bend Strength

Cold-rolled stainless steel angle trim products demonstrate superior bend resistance due to work hardening. For example, hot-rolled 304 angles achieve **≥205 MPa yield strength**, while cold-drawn variants reach **≥350 MPa**, suitable for seismic-resistant architectural frameworks.

Identification & Marking

Each stainless steel angle brackets is laser-etched with:

- Material Grade (e.g., SUS316L)

- Standard Code (e.g., ASTM A554)

- Heat Number for traceability

- Dimensions (L×W×Thickness)

Custom QR codes or client-specific logos are available for bulk orders.

Weight Calculation Formula

Weight (kg/m) =

Example: For a 50×50×5mm stainless steel angle iron:

.

Why Stainless Steel Angles May Rust?

Despite corrosion resistance, rust occurs under specific conditions:

- Chloride Exposure: Coastal environments or de-icing salts degrade the chromium oxide layer, causing pitting.

- Mechanical Abrasion: Scratches from improper handling or welding tools create galvanic corrosion sites.

- Low Oxygen Environments: Stagnant water or crevices accelerate localized corrosion in 304-grade angles.

- Iron Contamination: Residual iron particles from carbon steel tools trigger electrochemical reactions.

Preventive Measures:

- Select stainless steel angle brackets with 316L (2.5% Mo) for marine/chemical exposure.

- Passivate welded joints to restore chromium oxide layers post-fabrication.

- Use pH-neutral cleaners (6–8) to avoid surface degradation.

Why Choose Our Stainless Steel Angles?

- Precision Engineering: CNC-controlled laser cutting ensures ±0.1mm accuracy for stainless steel angle trim applications.

- Global Compliance: Certified to ASTM, EN, and ISO standards for structural reliability.

- Custom Solutions: Tailored stainless steel angle iron profiles (e.g., asymmetric legs, perforated designs) for OEM projects.

- Rapid Turnaround: 7–14 days lead time for bulk orders of stainless steel angle brackets.

- Sustainability: 100% recyclable materials with ISO 14001-compliant production.