StockSteel

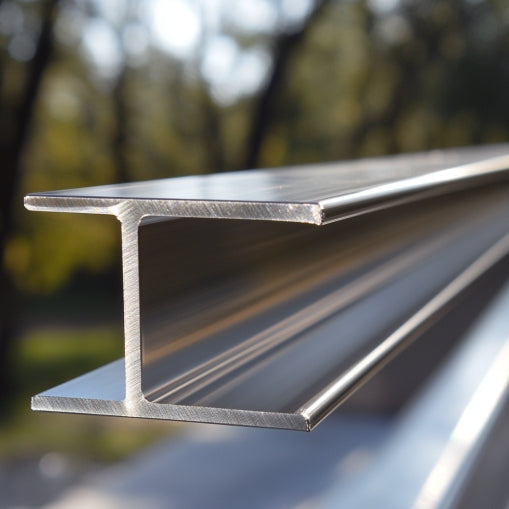

Stainless Steel H-Beam | High-Temp Industrial Loads

Stainless Steel H-Beam | High-Temp Industrial Loads

Regular price

$550.00 SGD

Regular price

Sale price

$550.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

Stainless Steel H-Beam Product Details

Specifications, Hardness, Sizes, Properties & Manufacturing Process

| Category | Details |

|---|---|

| Material Grades | wholesale stainless steel h beam: 304/304L, 316/316L, 321, 2205 (Duplex), 310S |

| Size Range | Flange Width: 50mm–600mm Web Height: 100mm–1200mm Custom lengths up to 18m |

| Thickness | Flange: 5mm–40mm Web: 6mm–50mm (±0.5% tolerance) |

| Surface Finish | Pickled, Polished (No.4/HL), Bead-Blasted, Hot-Dip Galvanized (optional) |

| Hardness (HV) | • 304: 150–200 HV • 316L: 130–180 HV • Duplex 2205: 280–320 HV |

| Process Methods | Hot Rolling, Laser Cutting, Welded (SAW/ERW), Annealed, Cold Formed |

| Certifications | ASTM A554, EN 10088-3, JIS G4304, ISO 9001, CE, NACE MR0175 |

| Applications | Structural Frameworks (advanced stainless steel h beam), Bridges, Automated Machinery (automation stainless steel h beam) |

Key Performance Properties

Tensile Strength

Advanced stainless steel h beam grades like 316L and Duplex 2205 exhibit exceptional tensile strength due to their alloy composition:

- 316L: Tensile strength ≥485 MPa, ideal for corrosive environments like chemical plants.

- Duplex 2205: Combines austenitic and ferritic phases, achieving ≥620 MPa tensile strength for high-stress applications such as offshore platforms.

- 304: Provides ≥520 MPa tensile strength, widely used in architectural frameworks due to its balance of strength and formability.

Bend Strength

Cold-formed automation stainless steel h beam products demonstrate superior bend resistance. For example:

- Hot-rolled 304 H-beams achieve ≥205 MPa yield strength, while cold-formed variants reach ≥350 MPa, suitable for seismic-resistant structures.

- Duplex 2205 H-beams maintain bend strength even at high temperatures (up to 300°C), critical for industrial automation systems.

Identification & Marking

Each wholesale stainless steel h beam is laser-etched with traceable identifiers:

- Material Grade (e.g., SUS316L).

- Standard Code (e.g., ASTM A554).

- Heat Number for quality tracking.

- Dimensions (Flange × Web × Length).

Custom QR codes or client-specific markings are available for OEM orders.

Weight Calculation Formula

Weight (kg/m) =

Example: For a 200mm (flange) × 10mm (flange thickness) × 300mm (web) × 12mm (web thickness) H-beam:

.

Why Stainless Steel H-Beams May Rust?

Despite their corrosion resistance, rust can occur under specific conditions:

- Chloride-Induced Corrosion: Coastal environments or exposure to de-icing salts degrade the chromium oxide layer, causing pitting.

- Mechanical Damage: Scratches from improper handling or welding compromise surface integrity.

- Galvanic Corrosion: Direct contact with carbon steel or copper in humid settings creates electrochemical cells.

- High-Temperature Oxidation: Prolonged exposure to >300°C oxidizes surfaces, especially in 304-grade beams.

- Contaminant Accumulation: Organic residues (e.g., grease) trap moisture, accelerating localized corrosion.

Preventive Measures:

- Use advanced stainless steel h beam grades like 316L (2.5% Mo) for marine or chemical exposure.

- Passivate welded joints to restore chromium oxide layers post-fabrication.

- Implement regular cleaning with pH-neutral detergents to remove contaminants.

Why Choose Our Stainless Steel H-Beams?

- Precision Manufacturing: CNC-controlled hot rolling ensures ±0.1mm dimensional accuracy for automation stainless steel h beam systems.

- Global Compliance: Certified to ASTM, EN, and ISO standards, guaranteeing structural reliability.

- Bulk Order Efficiency: Wholesale stainless steel h beam orders (100+ tons) ship within 10–15 days with volume discounts.

- Custom Solutions: Tailored H-beam profiles (asymmetric flanges, perforated webs) for specialized machinery and automation lines.

- Sustainability: 100% recyclable materials and energy-efficient production processes (ISO 14001 certified).