StockSteel

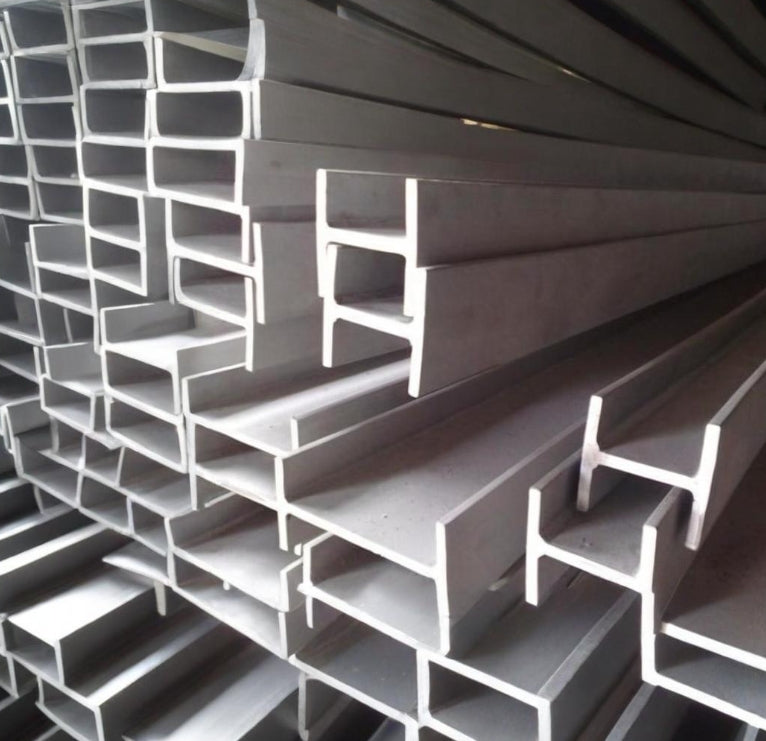

Stainless Steel H Beam | Premium Structural Durability

Stainless Steel H Beam | Premium Structural Durability

Couldn't load pickup availability

Stainless Steel H Beam | Premium Structural Durability

Product Specifications

| Property | Details |

|---|---|

| Material Standard | ASTM A276/A479 (Austenitic 316/304), EN 1.4301 (304), EN 1.4401 (316), JIS SUS316L |

| Dimensions | Flange Width: 100–500 mm |

| Surface Finish | Hot-rolled (HR) or cold-rolled (CR), No.1 (hot-rolled annealed), No.4 (brushed), or customized |

| Hardness (Rockwell B) | 304: ≤ 92 HRB |

| Yield Strength | 304: ≥ 205 MPa |

| Tensile Strength | 304: ≥ 515 MPa |

| Elongation | 304: ≥ 40% |

Key Attributes & Processing

| Category | Description |

|---|---|

| Chemical Composition | 304: 18% Cr, 8% Ni |

| Heat Treatment | Solution annealing (1040–1120°C) for stress relief and corrosion resistance optimization |

| Cold/Hot Rolling | Precision cold rolling (±0.5 mm tolerance) for tight dimensional control or hot rolling for structural bulk |

| Magnetic Properties | Austenitic grades (304/316) are non-magnetic; duplex grades exhibit partial magnetism |

Performance Highlights

Tensile & Bending Strength

The stainless steel h beam achieves exceptional tensile strength, with Grade 316 exceeding 550 MPa, ideal for load-bearing structures like bridges and industrial frameworks. Its bending performance is enhanced by the austenitic microstructure, which allows elongation rates above 35%, reducing fracture risks during seismic events. For high-strength applications, duplex variants (custom stainless steel h beam) provide tensile strength over 620 MPa, outperforming traditional carbon steel in corrosive environments.

Identification & Marking

Each beam is laser-etched with:

- Material Grade (e.g., 304, 316, duplex).

- Batch Number for traceability (ISO 10474 certification).

- Manufacturer Logo and compliance marks (ASTM/EN/JIS).

Weight Calculation

Calculate beam weight using:

Example: A 200×200×8×12 beam (flange: 200×12 mm, web: 200×8 mm):

Corrosion Resistance & Rust Prevention

While stainless steel h beam offers superior corrosion resistance, localized rust may occur under extreme conditions:

- Chloride Exposure: Coastal or de-icing environments can cause pitting in 304 grades. Upgrade to 316 or duplex for chloride-rich settings.

- Mechanical Damage: Scratches during installation expose the base metal. Passivation treatments restore the chromium oxide layer.

- High-Temperature Oxidation: Prolonged exposure above 870°C degrades the passive film. Use refractory coatings or opt for stabilized grades.

Why Choose Our Stainless Steel H Beam?

- Material Superiority: We use only best stainless steel h beam grades (304, 316, duplex) with mill test certificates, ensuring compliance with ASTM/EN standards.

- Customization Expertise: Tailor custom stainless steel h beam dimensions, surface finishes, and alloy compositions to meet project-specific demands (e.g., seismic reinforcement, coastal infrastructure).

- Global Certifications: ISO 9001, CE, and PED certifications guarantee product reliability for critical applications like nuclear facilities and offshore platforms.

- Fast Turnaround: 15–30 days lead time for standard sizes; expedited services available for urgent projects.

- Sustainability: Our beams contain 60–90% recycled content, aligning with green building initiatives (LEED/BREEAM compliance).