StockSteel

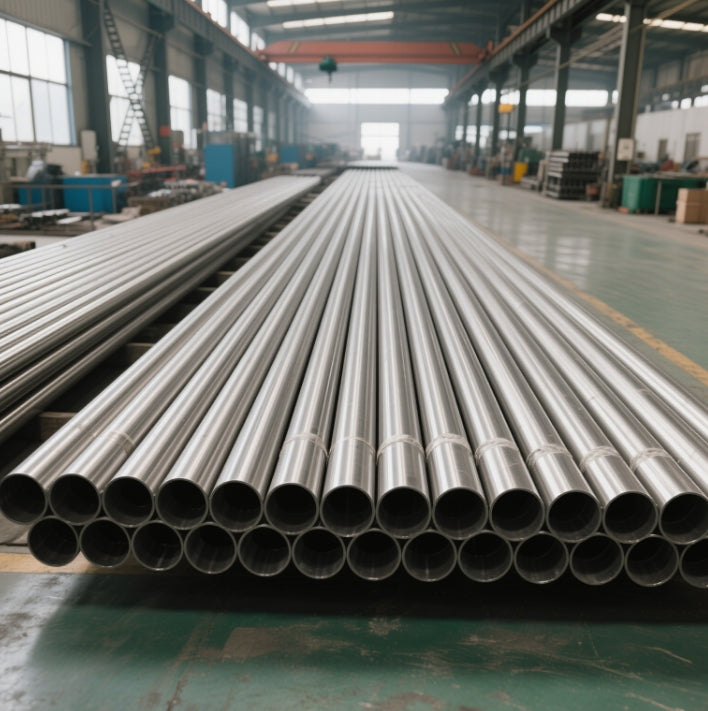

Stainless Steel Pipe | Ultra-Smooth 304L Industrial-Grade Tubes

Stainless Steel Pipe | Ultra-Smooth 304L Industrial-Grade Tubes

Couldn't load pickup availability

Stainless Steel Pipe | Ultra-Smooth 304L Industrial-Grade Tubes

Product Overview

Our 304L stainless steel pipes are engineered for unparalleled performance in demanding industrial environments. Designed with a low-carbon composition and ultra-smooth mirror-polished finish, these tubes excel in applications requiring corrosion resistance, hygienic standards, and mechanical durability. Ideal for stainless steel exhaust flex pipe systems, chemical processing, and stainless steel vent pipe installations, they combine precision manufacturing with global certifications to meet ASTM, ASME, and ISO standards.

Technical Specifications

| Property | 304L (UNS S30403) |

|---|---|

| Standards | ASTM A312, A213, ASME SA213 |

| Material Grade | Austenitic (Low Carbon) |

| Outer Diameter (OD) | 6mm – 762mm (1/4" – 30") |

| Wall Thickness | 0.35mm – 60mm |

| Hardness (HRB) | ≤90 |

| Tensile Strength | ≥485 MPa |

| Yield Strength | ≥170 MPa |

| Elongation | ≥40% |

| Surface Finish | Mirror Polished, Pickled, Annealed |

| Processing | Seamless/Cold-Drawn or Welded |

Key Attributes

- Corrosion Resistance: Enhanced by 18-20% chromium and 8-12% nickel, with ≤0.03% carbon to prevent carbide precipitation during welding.

- Hygienic Design: Mirror-polished surfaces (Ra ≤0.3μm) inhibit bacterial growth, ideal for food processing and pharmaceuticals.

- Thermal Stability: Withstands temperatures up to 870°C (1600°F), perfect for stainless steel exhaust flex pipe retrofits.

- Eco-Friendly: 100% recyclable with minimal environmental impact.

Detailed Performance Characteristics

Tensile & Bend Strength

- Tensile Strength: ≥485 MPa ensures structural integrity in high-pressure systems like hydraulic lines and stainless steel vent pipe networks.

- Bend Strength: The austenitic microstructure provides exceptional ductility, retaining roundness even under tight-radius bends required for stainless steel threaded pipe fittings installations.

Identification Methods

- Laser Etching/Stamping: Permanent markings include grade (e.g., "304L"), OD, thickness, and heat number per ASTM A480.

- Certification: Mill Test Reports (MTRs) validate chemical composition (Cr, Ni, C) and mechanical properties for full traceability.

Weight Calculation

Use the formula:

Example: A 100mm OD pipe with 5mm wall thickness weighs ~11.6 kg/m.

Causes of Stainless Steel Rust

Despite its corrosion resistance, rust can occur under:

- Chloride Exposure: High chloride concentrations (e.g., seawater) disrupt the passive chromium oxide layer, causing pitting.

- Mechanical Damage: Scratches or abrasions expose raw metal to oxidation.

- Galvanic Corrosion: Contact with dissimilar metals (e.g., carbon steel) in conductive fluids accelerates degradation.

- Improper Welding: Carbon precipitation in heat-affected zones reduces corrosion resistance, mitigated by using low-carbon 304L.

Applications

- Exhaust Systems: Stainless steel exhaust flex pipe retrofits leverage high-temperature stability and bend strength.

- Plumbing: Stainless steel threaded pipe fittings ensure leak-proof joints in water supply and industrial pipelines.

- Ventilation: Stainless steel vent pipe installations resist acidic fumes in chemical plants.

Why Choose Our Stainless Steel Pipes?

- Certified Quality: Compliant with ASTM, ASME, and ISO standards, backed by third-party inspections.

- Global Stock: Immediate dispatch of custom sizes (e.g., stainless steel vent pipe up to 30" OD).

- Custom Solutions: Tailored OD, wall thickness, and surface finishes (e.g., mirror polish) for seamless integration.

- Technical Expertise: 20+ years of experience in precision tubing for extreme environments.

- Sustainability: Fully recyclable material with a low carbon footprint.