StockSteel

Stainless Steel Plates | ASTM-Certified 316 Grade | Factory Direct

Stainless Steel Plates | ASTM-Certified 316 Grade | Factory Direct

Couldn't load pickup availability

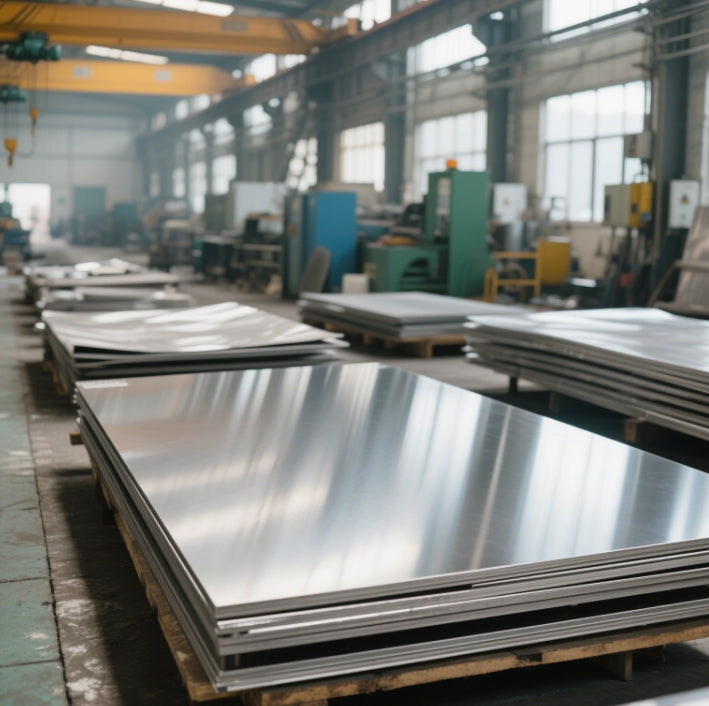

Premium Stainless Steel Plates | ASTM-Certified 316 Grade | Factory Direct

Product Overview

Engineered for industrial excellence, our stainless steel plates combine superior corrosion resistance, unmatched durability, and compliance with ASTM A240/AISI 316 standards. Designed for heavy-duty applications like stainless steel railroad tie plate systems, chemical processing, and marine environments, these plates are cold-rolled or hot-rolled to meet precise specifications. With factory-direct pricing and global certifications, we deliver reliability for infrastructure, construction, and high-temperature projects.

Technical Specifications

| Attribute | Details |

|---|---|

| Material Grade | 316/316L stainless steel (Chromium-Nickel-Molybdenum Austenitic Alloy) |

| Thickness Range | 0.1mm – 100mm (Customizable to ±0.05mm tolerance) |

| Standard Dimensions | 4x8 FT, 1500x3000mm, 1500x6000mm (Custom widths up to 2500mm available) |

| Hardness | 316: HRB 88 max / 316L: HRB 85 max (Annealed Condition) |

| ASTM Certification | ASTM A240/AISI, ISO 9001, SGS, BV |

| Surface Finish | 2B (Cold-rolled smooth), BA (Bright Annealed), No.4, HL, 8K Mirror, Custom |

| Processing | Laser Cutting, CNC Machining, Cold/Hot Rolling, Welding, Punching |

Key Properties

1. Tensile Strength

316 stainless steel plates exhibit a tensile strength of ≥515 MPa, ensuring structural integrity under extreme loads. The addition of molybdenum (2-3%) enhances resistance to pitting and crevice corrosion, making it ideal for chloride-rich environments like coastal railways or chemical plants.

2. Bend Strength

With a minimum yield strength of 205 MPa, these plates withstand bending angles up to 180° without cracking. Cold-rolled variants achieve higher bend ductility, suitable for forming complex shapes in stainless steel railroad tie plate fabrication.

3. Weight Calculation

Calculate plate weight using:

Example: A 4x8 FT (1.22x2.44m), 8mm plate weighs:

4. Identification Marking

Each plate is laser-etched with:

- Material Grade (316/316L)

- ASTM Certification Code

- Batch Number & Manufacturer’s Logo

5. Why Stainless Steel Rusts

While 316 stainless steel plates resist oxidation, rust may occur under:

- Chloride Exposure: Coastal or de-icing salt environments accelerate pitting corrosion by breaking the chromium oxide layer.

- Mechanical Damage: Scratches from carbon steel tools create localized galvanic corrosion.

- High-Temperature Oxidation: Prolonged exposure above 800°C depletes chromium content, reducing corrosion resistance.

Prevention: Regular passivation treatments and avoiding contact with incompatible metals.

Applications

- Rail Infrastructure: Stainless steel railroad tie plate systems for bridges, tunnels, and heavy-load tracks.

- Chemical Processing: Reactors, pipelines, and storage tanks resistant to acids/alkalis.

- Architectural: Structural cladding, elevators, and coastal building supports using 316 stainless steel plate.

- Marine: Ship components, offshore platforms, and desalination plants.

Why Choose Our Stainless Steel Plates?

- ASTM-Certified Quality: Rigorous third-party inspections (SGS, BV) ensure compliance with global standards.

- Factory Direct Pricing: Eliminate middlemen for cost savings up to 20% versus competitors.

- Customization: Tailor dimensions, finishes, and processing (e.g., laser-cut stainless steel railroad tie plate designs).

- 10-Year Corrosion Warranty: Guaranteed performance in harsh environments.

- Sustainability: 100% recyclable material with ISO 14001-certified production.

- Fast Delivery: 7-30 days lead time, backed by global logistics partnerships.