StockSteel

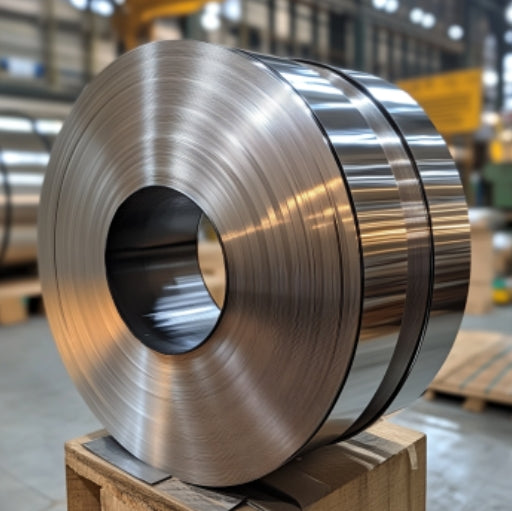

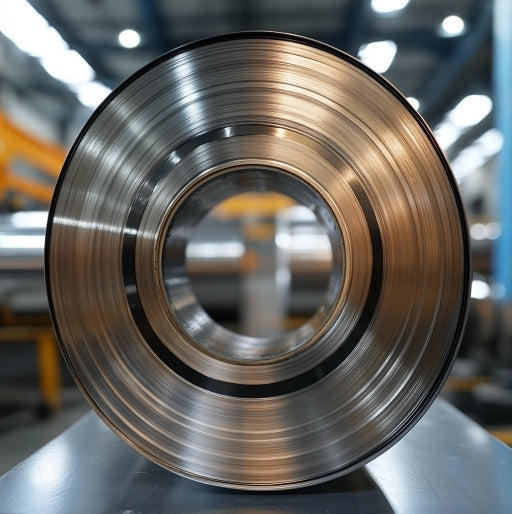

Custom Stainless Steel Strip Solutions | Trim & Roll Options

Custom Stainless Steel Strip Solutions | Trim & Roll Options

Couldn't load pickup availability

Stainless Steel Metal Strips Product Details

Specifications & Properties

| Parameter | Details |

|---|---|

| Material Grades | 304, 316L, 430, 410, 301, 201, 2205 (Duplex), 630 (17-4PH) |

| Thickness Range | 0.1–6.0 mm (Cold Rolled: 0.1–3.0 mm; Hot Rolled: 1.5–6.0 mm) |

| Width | 10–600 mm (Standard) / Customizable up to 1,219 mm |

| Surface Finish | 2B, BA, No.4, HL, Mirror Polished, Annealed, Pickled |

| Hardness (HV) | Austenitic (150–200 HV) |

| Tolerance | ±0.01 mm (Thickness) / ±0.2 mm (Width) |

| Density | 7.93 g/cm³ (304/316) / 7.75 g/cm³ (430/410) |

| Processing | Cold Rolling, Hot Rolling, Precision Slitting, Annealing, Tempering |

Mechanical & Functional Properties

Tensile Strength

stainless steel metal strips exhibit superior tensile strength, ranging from 515–860 MPa depending on the grade and processing method

. For instance:

- Austenitic Grades (304/316L): 515–620 MPa (Annealed) / 860 MPa (Full Hard)

- Martensitic Grades (410/420): 760–827 MPa (Tempered)

- Duplex Grades (2205): 620–750 MPa (Cold Worked)

Cold-rolled stainless steel strip roll achieves higher strength due to work hardening, making it ideal for springs, automotive components, and industrial blades.

Bending Strength

Bending strength correlates with yield strength and ductility. Austenitic grades (e.g., 301) offer 205–310 MPa yield strength, enabling deep drawing and complex forming without cracking. Precision slitting ensures edge uniformity for stainless steel seam strips used in welding and sealing applications.

Identification & Marking

Stainless steel strips are marked using laser engraving or color codes per international standards:

- ASTM/ASME: Grade designation (e.g., “316L”), heat number, and manufacturer’s logo.

- ISO/DIN: Material numbers (e.g., 1.4404 for 316L) and dimensional tolerances.

Certifications include Mill Test Reports (MTRs) with chemical composition and mechanical data.

Weight Calculation

Weight (kg/m²) = Thickness (mm) × Width (mm) × Length (m) × Density (g/cm³) / 1,000

Example: A 1.0 mm × 300 mm × 1 m stainless steel strip roll (304 grade) weighs:

1.0 × 300 × 1 × 7.93 / 1,000 = 2.379 kg/m².

For coils, total weight = kg/m² × coil length (m).

Why Does Stainless Steel Rust?

While stainless steel metal strips are corrosion-resistant, rust can occur under specific conditions:

- Chloride Exposure: Chlorides (e.g., seawater, de-icing salts) disrupt the passive chromium oxide layer, leading to pitting corrosion.

- Mechanical Damage: Scratches or abrasions expose raw steel to oxidation.

- Low Chromium Content: Grades with <10.5% chromium (e.g., 430) lack sufficient corrosion resistance.

- Galvanic Corrosion: Contact with dissimilar metals (e.g., carbon steel) in electrolytes accelerates rusting.

- High-Temperature Oxidation: Prolonged exposure above 400°C degrades protective layers in non-stabilized grades (e.g., 304 vs. 321).

Regular cleaning with pH-neutral solutions and avoiding abrasive tools mitigates these risks.

Why Choose Our Stainless Steel Strips?

- Material Diversity: Over 20 grades, including super duplex (2507), precipitation-hardening (17-4PH), and high-temperature alloys (310S).

- Precision Manufacturing: CNC-controlled cold rolling and slitting ensure ±0.01 mm tolerance for aerospace and medical applications.

- Global Certifications: ASTM A240, A666, EN 10088-2, and PED 2014/68/EU compliance.

- Custom Solutions: Tailored surface finishes (e.g., No.4 for kitchenware), custom widths, and heat treatment (annealed, tempered).

- Quality Assurance: Third-party testing for hardness (Rockwell/Vickers), corrosion resistance (ASTM G48), and intergranular corrosion.