StockSteel

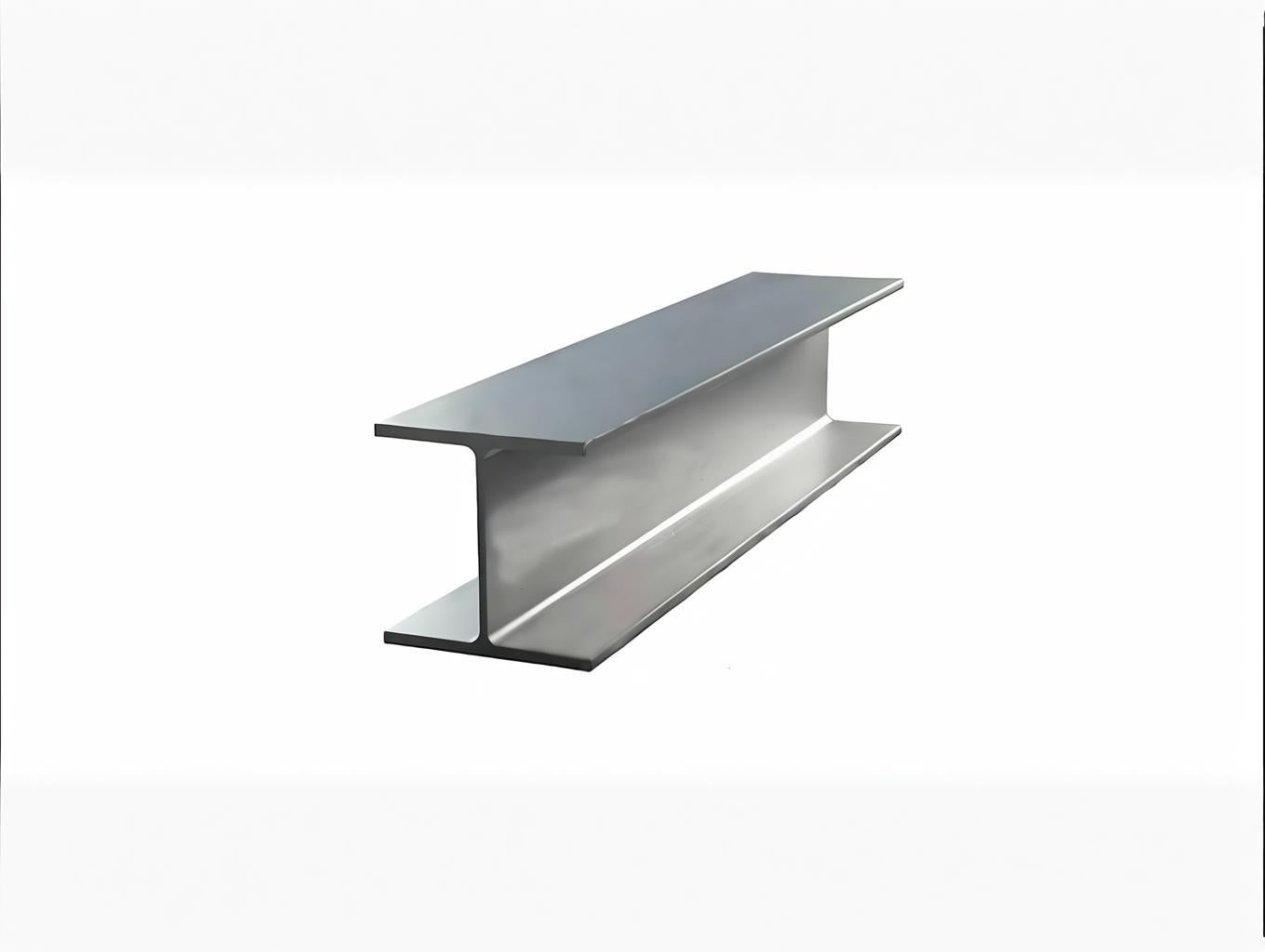

Custom-Fabricated H-Beam Solutions | Hot-Dip Galvanized 304 Stainless Steel for Modular Warehouses & Bridge Abutments

Custom-Fabricated H-Beam Solutions | Hot-Dip Galvanized 304 Stainless Steel for Modular Warehouses & Bridge Abutments

Couldn't load pickup availability

Engineered for High-Performance Structural Frameworks

Crafted through hot-rolled molding precision, these stainless steel H-beams achieve ASTM-compliant durability with ±1% dimensional accuracy, ideal for heavy-load industrial systems. The adjustable flange dimensions (100–1,000 mm width, 8–28 mm thickness) and customizable web profiles (96–300 mm width, 6–16 mm thickness) enable seamless integration into modular assemblies, seismic-resistant trusses, and automated production lines.

| Parameter | Specification |

|---|---|

| Material Grades | 304 / 316 / 316L |

| Thickness Range | 0.8–25 mm (±1% tolerance) |

| Processing Services | Cutting, Welding, Punching |

| Certifications | ISO9001, ASTM, EN, JIS |

| MOQ & Lead Time | 2 Tons, 8–14 Days |

Agile Fabrication for Global Industrial Demands

Optimized for mechanical manufacturing and structural engineering, these beams support custom-length orders and precision decoiling, reducing material waste by 30–40% compared to conventional I-beams. The natural mill finish eliminates secondary surface treatments, while non-alloy steel ensures corrosion resistance in harsh environments. With flexible L/C and T/T payment options and 5–10-day expedited shipping, projects stay on schedule without budget compromises.

Superior Load-Bearing Efficiency in Extreme Conditions

Engineered to withstand torsional stress and dynamic fatigue, the H-shaped geometry maximizes weight-to-strength ratios for applications like offshore platform bases and heavy machinery supports. Compliant with AISI, EN, and JIS standards, the hot-rolled stainless steel core guarantees weld-ready edges and bolt-hole accuracy, while 1,000 kg unit packaging ensures secure global logistics and damage-free delivery.