StockSteel

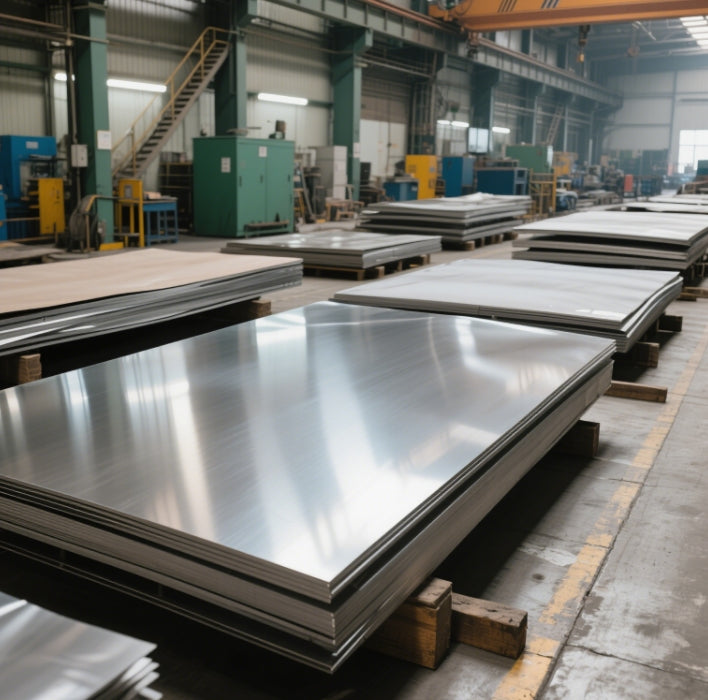

Superior Stainless Steel Metal Plate | 2B/HL Finish & ASTM Certified

Superior Stainless Steel Metal Plate | 2B/HL Finish & ASTM Certified

Couldn't load pickup availability

Superior Stainless Steel Metal Plate | 2B/HL Finish & ASTM Certified

Product Specifications

| Parameter | Details |

|---|---|

| Material | 304/304L/316/316L Stainless Steel (ASTM A240, EN 1.4301/1.4404) |

| Thickness | 0.3–100 mm (Cold-rolled: 0.3–6 mm; Hot-rolled: 3–100 mm; stainless steel plate thickness chart available) |

| Dimensions | Standard: 1000×2000 mm, 1219×2438 mm, 1500×3000 mm; Custom sizes for stainless steel plates and cups |

| Hardness | HV 150–220, HRB ≤95, HB ≤210 (Annealed state) |

| Surface Finish | 2B Finish (Cold-rolled, smooth, semi-reflective), HL (Hairline) (Linear brushed texture), No.4, BA, Mirror |

| Certifications | ASTM A240, EN 10088-2, JIS G4303, ISO 9445 |

| Density | 7.93 g/cm³ (304), 7.98 g/cm³ (316) |

Key Properties

Tensile Strength

Our stainless steel plates exhibit exceptional tensile strength, ranging from ≥515 MPa (304) to ≥520 MPa (316). The high nickel (8–12%) and chromium (18–20%) content ensures superior ductility, achieving ≥40% elongation, making them ideal for deep-drawn applications like stainless steel plates and cups. The 316L variant, with added molybdenum (2–3%), resists pitting in chloride-rich environments, such as marine or chemical processing.

Bending Strength

Optimized for cold-forming, these plates withstand tight-radius bends (up to 180°) without cracking. The strain hardening exponent (n-value) of 0.32–0.45 ensures uniform deformation, critical for precision components. Post-welding, the heat-affected zone retains ≥90% of the base metal’s strength, essential for structural integrity.

Identification & Weight Calculation

Marking Methods

- Laser Etching: Permanent grade identification (e.g., "304," "316L") on plate edges.

- QR Codes: Traceability linked to batch-specific certifications from stainless steel plate manufacturer partners.

- Color Coding: Optional oxide tints (e.g., gold, bronze) for decorative alignment with architectural designs.

Weight Formula

Example: A 3 mm × 1.2 m × 2.4 m 304 plate weighs 3 × 1.2 × 2.4 × 7.93 = 68.6 kg.

Why Stainless Steel May Corrode?

Despite its corrosion resistance, stainless steel can rust under specific conditions:

- Chloride Exposure: Prolonged contact with seawater or de-icing salts may cause pitting. Grades like 316L mitigate this with molybdenum.

- Mechanical Damage: Scratches or grinding disrupt the passive chromium oxide layer. Our 2B/HL finishes minimize defects through controlled rolling and polishing.

- Galvanic Corrosion: Contact with carbon steel or copper alloys in humid environments. Use insulating gaskets in mixed-metal assemblies.

- High-Temperature Oxidation: Continuous exposure above 870°C degrades chromium’s protective oxide. Ceramic coatings are recommended for extreme heat.

Why Choose Our Stainless Steel Plates?

- Certified Quality: Compliance with ASTM A240 and EN 10088-2, validated by third-party labs.

- Custom Solutions: Tailored stainless steel plate thickness chart options and finishes (e.g., HL for elevators, 2B for food processing).

- Global Standards: Adherence to JIS, DIN, and ISO specifications for seamless international integration.

- Technical Expertise: 20+ years as a leading stainless steel plate manufacturer, offering free fabrication guidance (welding, machining, passivation).

- Fast Delivery: 15–30-day lead time with anti-rust packaging for global shipments.