StockSteel

Sustainable stainless steel plate | Eco-Conscious Manufacturing Practices

Sustainable stainless steel plate | Eco-Conscious Manufacturing Practices

Couldn't load pickup availability

Sustainable Stainless Steel Plate | Eco-Conscious Manufacturing Practices

Product Overview

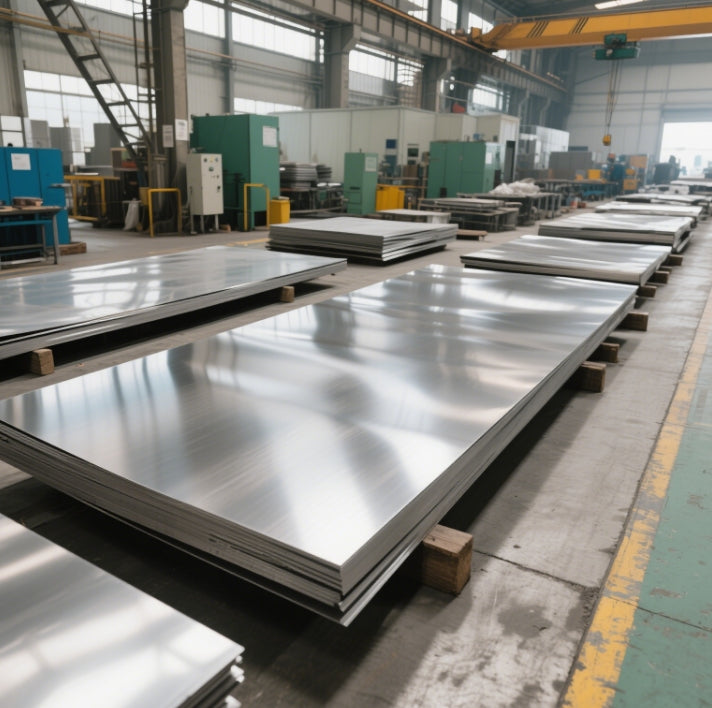

Our sustainable stainless steel plates are crafted with cutting-edge eco-friendly technologies, combining durability, recyclability, and reduced environmental impact. Designed for construction, industrial, and architectural applications, these plates are ideal for stainless steel deck plates, stainless steel door plates, and stainless steel kick plates, offering superior corrosion resistance and structural integrity. Manufactured with 70% recycled content and low-carbon processes, they comply with global sustainability certifications like ISO 14001 and LEED.

Specifications & Properties

| Property | Details |

|---|---|

| Material | 304, 316L, 430 stainless steel (70% recycled content) |

| Thickness | 0.5mm–30mm (customizable for stainless steel kick plates or heavy-duty decking) |

| Width | 500mm–2500mm (adjustable for architectural or industrial use) |

| Length | 1m–6m (standard or custom lengths) |

| Surface Finish | Brushed, PVD Coated (eco-friendly), Embossed (anti-slip textures) |

| Hardness | 304: HRB 70–88; 316L: HRB 75–95; 430: HRB 80–95 |

| Certifications | ISO 14001, LEED, RoHS, ASTM A240 |

| Processing | Laser Cutting, Cold Rolling, Electro-Polishing, Low-Energy Welding |

Key Features

1. Tensile & Bend Strength

- Tensile Strength: Ranges from 515 MPa (304 grade) to 620 MPa (316L), ensuring exceptional load-bearing capacity for structural applications like stainless steel deck plates in marine environments. Cold-rolled variants achieve higher yield strength (up to 310 MPa), minimizing deformation under dynamic stress.

- Bend Strength: Engineered to flex without cracking, even at sub-zero temperatures. This flexibility is critical for stainless steel door plates requiring precise shaping and impact resistance.

2. Identification & Weight Calculation

- Identification: Grades are laser-etched per ASTM/EN standards (e.g., "316L" for marine-grade steel) with traceability codes for quality assurance.

- Weight Formula:Example: A 3mm × 1m × 2m plate weighs 47.58 kg.

3. Corrosion Resistance & Rust Prevention

Stainless steel’s chromium content (≥10.5%) forms a self-repairing chromium oxide layer, blocking oxidation. However, localized rust may occur due to:

- Chloride Exposure: Coastal or de-icing environments accelerate pitting. Our 316L grade adds 2-3% molybdenum for enhanced chloride resistance.

- Mechanical Damage: Scratches from abrasive tools compromise the oxide layer. Electro-polishing restores surface integrity and corrosion resistance.

- Galvanic Corrosion: Direct contact with carbon steel triggers electrochemical reactions. We recommend insulating gaskets for mixed-material installations.

Applications

- Architectural Safety: Anti-slip stainless steel deck plates for rooftop walkways and industrial platforms.

- Building Protection: Durable stainless steel door plates and kick plates for high-traffic entrances.

- Marine & Infrastructure: Corrosion-resistant plates for docks, bridges, and coastal structures.

Why Choose Our Stainless Steel Plates?

-

Eco-Conscious Manufacturing:

- 70% Recycled Content: Reduces reliance on virgin materials and lowers carbon footprint.

- Low-Energy Processes: Solar-powered cold rolling and laser cutting minimize energy consumption.

- Zero-Waste Policy: 95% of production scrap is recycled into new batches.

-

Certified Quality:

- Compliant with ISO 14001 (environmental management) and RoHS (hazardous substance restrictions).

- Rigorous testing for heavy metal migration and salt spray resistance (1,000+ hours).

-

Custom Solutions:

- Tailored dimensions, textures (e.g., anti-slip embossing), and PVD color coatings.

- Fast prototyping (5–7 days) and global logistics support.