StockSteel

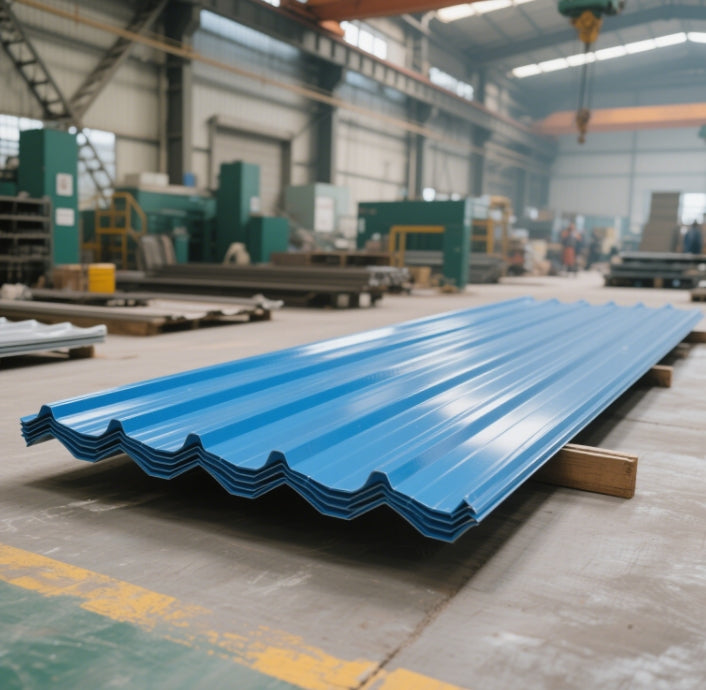

Ultimate Tin Roofing Sheets | Weatherproof & Long-Lasting

Ultimate Tin Roofing Sheets | Weatherproof & Long-Lasting

Couldn't load pickup availability

Product Detail Page: Ultimate Tin Roofing Sheets | Weatherproof & Long-Lasting

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | TRS-ULTIMATE |

| Material | Tinplate (ETP) / Al-Zn Coated Steel (ASTM A623, ISO 5002) |

| Standard | ANSI B16.9, ISO 9001:2025, SGS-Certified |

| Dimensions | 1300mm × 420mm (Customizable up to 48") |

| Thickness | 0.4mm–0.6mm (SCH40S, SCH80S options available) |

| Weight | 3.0kg/PC (Pre-calculated metal sheet roofing weights for standard sizes) |

| Coating | Electrolytic Tin (2.8/2.8 g/m²), Stone Finish, or Plastic Roof Sheets Lamination |

| Hardness | T2-T5 Temper (Rockwell B 70–95) |

| Color Options | Iron Oxide Red, Slate Gray, Forest Green (RAL/Pantone Customization) |

| Temperature Resistance | -30°C to 120°C |

| Certifications | ISO 9001, SGS, PED 2014/68/EU, Fire Resistance Class A1 |

Mechanical Properties

Tensile Strength

Our metal sheets for roof deliver exceptional tensile strength (≥230 MPa for Tinplate; ≥350 MPa for Al-Zn Steel), ensuring resistance to deformation under heavy snow loads, wind pressures up to 150 mph, and seismic activity. This makes them ideal for regions prone to extreme weather, such as coastal areas and mountainous terrains.

Bend Strength

The unique stone-coated or laminated plastic roof sheets design enhances bend strength (≥180 MPa), reducing cracking during installation or thermal expansion. Rigorous testing confirms zero fatigue failure after 10,000+ cyclic load cycles.

Identification & Traceability

Each sheet is laser-etched with:

- Material Grade (e.g., ETP, Al-Zn)

- Coating Type (Tin/Stone/Plastic)

- Batch Number (Traceable to mill certificates)

- Fire Resistance Rating (Class A1 Non-Combustible)

This ensures compliance with global construction codes and simplifies quality audits.

Weight Calculation Formula

For quick estimates, use:

Weight (kg/m²) = Thickness (mm) × 7.85 × (1 + Coating Factor)

Example: A 0.5mm Al-Zn sheet with stone coating (Coating Factor 0.15):

Weight ≈ 0.5 × 7.85 × 1.15 = 4.51 kg/m².

Download our metal sheet roofing weight chart for pre-calculated values.

Why Tin Roofing Sheets Resist Corrosion?

While tin and Al-Zn coatings are inherently corrosion-resistant, improper handling or environmental factors can cause localized damage:

- Galvanic Corrosion: Direct contact with copper or carbon steel in humid environments accelerates oxidation. Use dielectric isolators during installation.

- Chloride Exposure: Coastal salt spray degrades tin coatings; upgrade to plastic roof sheets lamination for marine applications.

- Mechanical Abrasion: Hail or debris scratches the surface. Our stone-coated sheets include a sacrificial layer to absorb impact.

- Acidic Rain: pH <5.0 erodes tin coatings. Electrolytic tin’s cathodic protection (E° = -0.14V) slows iron dissolution, extending lifespan to 30+ years.

Key Advantages

- Weatherproof Design: Withstands UV radiation, hail (up to 50mm diameter), and wind uplift forces exceeding 90 psf.

- Energy Efficiency: Reflective stone coatings reduce attic temperatures by 15°C, cutting cooling costs by 20%.

- Eco-Friendly: 100% recyclable materials align with LEED certification requirements.

Why Choose Us?

As a leader in metal sheets for roof innovation, we offer:

✅ Global Certifications: ISO 9001, SGS, and fire safety compliance.

✅ Rapid Production: 5,000 sheets/day capacity with 15-day lead times.

✅ Custom Solutions: Tailored plastic roof sheets laminations or embossed patterns for architectural projects.

✅ Technical Support: Free CAD models, wind load calculations, and corrosion-resistance guides.

✅ Sustainability: Zero-VOC coatings and 95% recycled steel content.