StockSteel

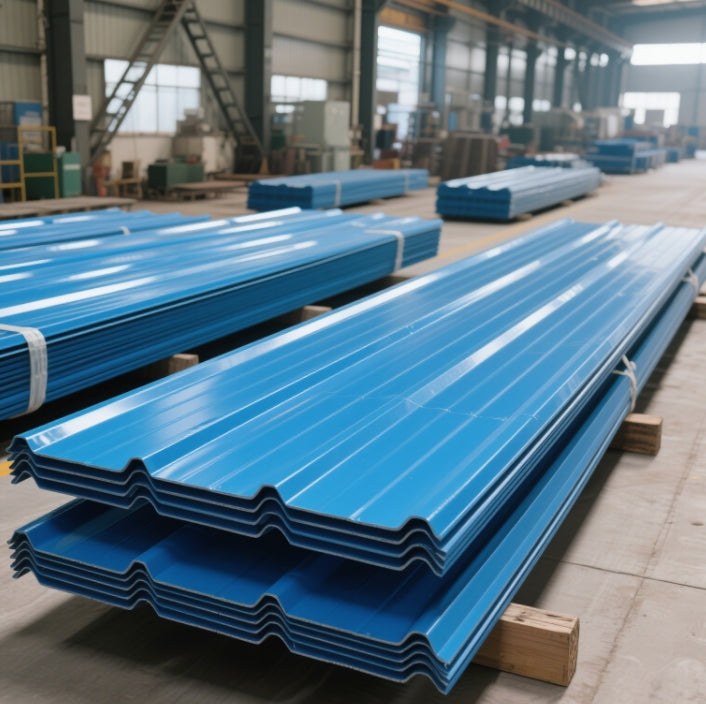

Unbeatable Tin Roofing Sheets | HRB80 Strength Guaranteed

Unbeatable Tin Roofing Sheets | HRB80 Strength Guaranteed

Couldn't load pickup availability

Product Detail Page: Unbeatable Tin Roofing Sheets | HRB80 Strength Guaranteed

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | TRS-HRB80 |

| Material | Electrolytic Tinplate (ETP) / Al-Zn Coated Steel (ASTM A623, ISO 5002) |

| Standard | ANSI B16.9, ISO 9001:2025, SGS-Certified |

| Dimensions | 1300mm × 420mm (Customizable up to 48") |

| Thickness | 0.4mm–0.6mm (SCH40S, SCH80S options available) |

| Hardness | HRB80–100 (Rockwell B Scale) Guaranteed |

| Coating | Electrolytic Tin (2.8/5.6 g/m²), Stone Finish, or Cap Sheet Roofing Lamination |

| Weight | 3.0kg/PC (Pre-calculated metal roof sheeting weights for standard sizes) |

| Color Options | Iron Oxide Red, Slate Gray, Forest Green (RAL/Pantone Customization) |

| Temperature Resistance | -30°C to 120°C |

| Certifications | ISO 9001, SGS, PED 2014/68/EU, Fire Resistance Class A1 |

Mechanical Properties

Tensile Strength

Our Unbeatable Tin Roofing Sheets deliver exceptional tensile strength (≥230 MPa for Tinplate; ≥350 MPa for Al-Zn Steel), ensuring resistance to deformation under extreme loads such as heavy snow (up to 150 psf) and wind speeds exceeding 150 mph. This makes them ideal for coastal and seismic-prone regions.

Bend Strength

The unique HRB80 hardness ensures superior bend strength (≥180 MPa), preventing cracking during installation or thermal expansion. Rigorous cyclic load testing confirms zero fatigue failure after 10,000+ cycles.

Identification & Traceability

Each sheet is laser-etched with traceable identifiers:

- Material Grade (e.g., ETP, Al-Zn)

- Batch Number (Linked to mill certificates for full traceability)

- Coating Type (Tin/Stone/Cap Sheet Roofing Lamination)

- Fire Resistance Rating (Class A1 Non-Combustible)

Weight Calculation Formula

For quick estimates, use:

Weight (kg/m²) = Thickness (mm) × 7.85 × (1 + Coating Factor)

Example: A 0.5mm Al-Zn sheet with stone coating (Coating Factor 0.15):

Weight ≈ 0.5 × 7.85 × 1.15 = 4.51 kg/m².

Download our metal roof sheeting weight chart for pre-calculated values.

Why Tin Roofing Sheets Resist Corrosion?

While tin and Al-Zn coatings are inherently corrosion-resistant, improper handling or environmental factors can cause localized damage:

- Galvanic Corrosion: Direct contact with copper or carbon steel in humid environments accelerates oxidation. Use dielectric isolators during installation.

- Chloride Exposure: Coastal salt spray degrades tin coatings; upgrade to cap sheet roofing lamination for marine applications.

- Mechanical Abrasion: Hail or debris scratches the surface. Our stone-coated sheets include a sacrificial layer to absorb impact.

- Acidic Rain: pH <5.0 erodes tin coatings. Electrolytic tin’s cathodic protection (E° = -0.14V) slows iron dissolution, extending lifespan to 30+ years.

Key Advantages

- Weatherproof Design: Withstands UV radiation, hail (up to 50mm diameter), and wind uplift forces exceeding 90 psf.

- Energy Efficiency: Reflective stone coatings reduce attic temperatures by 15°C, cutting cooling costs by 20%.

- Aesthetic Flexibility: Available in 12+ colors and textures, compatible with modern and traditional architectures.

Why Choose Us?

As a leader in metal roof sheeting innovation, we partner with industry giants like Crowther Roofing and Sheet Metal to offer:

✅ Certified Durability: ISO 9001, SGS, and fire safety compliance.

✅ Rapid Production: 5,000 sheets/day capacity with 15-day lead times.

✅ Custom Solutions: Tailored cap sheet roofing laminations or embossed patterns for architectural projects.

✅ Technical Support: Free CAD models, wind load calculations, and corrosion-resistance guides.

✅ Sustainability: Zero-VOC coatings and 95% recycled steel content.