StockSteel

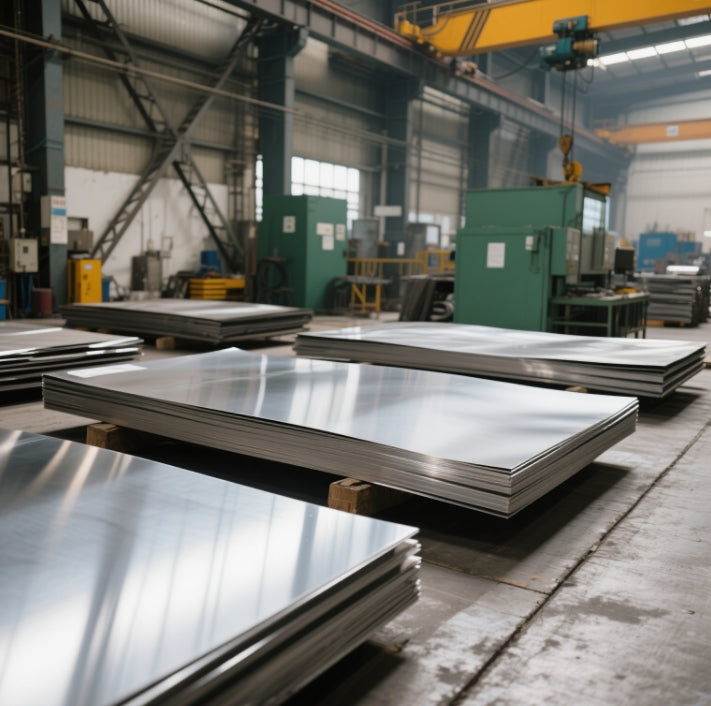

Versatile stainless steel plate | From Kitchenware to Architectural Designs

Versatile stainless steel plate | From Kitchenware to Architectural Designs

Couldn't load pickup availability

Versatile Stainless Steel Plate | From Kitchenware to Architectural Designs

Transform your projects with our ASTM-certified stainless steel plates, engineered for unparalleled durability and aesthetic appeal. Perfect for kitchenware, stainless steel wall plates, automotive components, and architectural designs, our plates combine corrosion resistance with versatile functionality.

Product Specifications

| Property | Value |

|---|---|

| Grade | ASTM A240 304, 316, 430; EN 1.4301, 1.4404 |

| Thickness | 0.5 mm – 30 mm (Customizable) |

| Width | 1000 mm – 2000 mm |

| Length | 2000 mm – 6000 mm |

| Hardness | ≤201 HBW (304); ≤217 HBW (430) |

| Surface Finish | 2B, BA, No.4, Hairline, Mirror, Embossed |

| Density | 7.93 g/cm³ (304); 7.70 g/cm³ (430) |

| Melting Point | 1398°C – 1454°C (304) |

Mechanical & Functional Properties

Tensile Strength

Our stainless steel plates boast tensile strengths ranging from 515 MPa (304) to 650 MPa (430), ensuring structural integrity under extreme loads. This makes them ideal for heavy-duty applications like stainless steel door kick plates and stainless steel wall plates, where resistance to deformation is critical. The yield strength of ≥205 MPa (304) guarantees stability in dynamic environments.

Bending Strength

With elongation rates up to 40% (304), our plates retain their integrity even after rigorous bending or forming. This ductility is essential for creating complex shapes, such as curved stainless steel licence plate screws or decorative architectural panels, without compromising strength.

Material Identification & Standards

Key Designations

- ASTM A240: Specifies requirements for chromium-nickel (304/316) and chromium (430) grades.

- EN 1.4301/1.4404: European standards equivalent to 304 and 316, ensuring global compatibility.

- JIS SUS304/SUS430: Japanese standards for automotive and construction applications.

Why Compliance Matters

Strict adherence to standards guarantees optimal chromium (18–20% in 304) and nickel (8–10% in 304) content, enhancing corrosion resistance and weldability. For example, stainless steel door kick plates require precise alloy ratios to withstand weathering and physical impact.

Weight Calculation

Calculate plate weight using the formula:

Example: A 2 mm × 1.2 m × 2.4 m 304 plate weighs:

Why Stainless Steel Corrodes?

Despite its resilience, stainless steel can rust under specific conditions:

- Chloride Exposure: Coastal environments or de-icing salts accelerate pitting corrosion, especially in grades like 430 with lower nickel content.

- Mechanical Damage: Scratches or contamination (e.g., iron particles) disrupt the chromium oxide layer, exposing the base metal to oxidation.

- Galvanic Corrosion: Contact with dissimilar metals (e.g., carbon steel) triggers electrochemical degradation.

- Improper Welding: Poor welding techniques reduce chromium’s protective effect, leading to intergranular corrosion.

Why Choose Our Stainless Steel Plates?

- Certified Quality: Every batch undergoes rigorous ASTM and EN standard testing for chemical composition and mechanical performance.

- Custom Fabrication: Precision laser cutting and CNC bending for stainless steel wall plates or door kick plates with flawless edges.

- Aesthetic Versatility: Choose from mirror, hairline, or embossed finishes to match architectural or industrial designs.

- Technical Expertise: Free consultation on welding, corrosion prevention, and design optimization for projects like stainless steel licence plate screws or structural cladding.