StockSteel

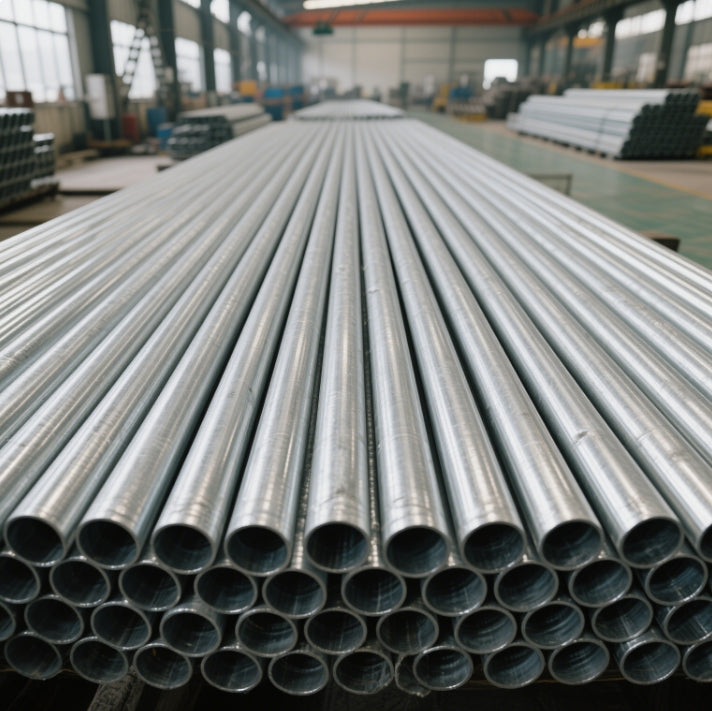

Weatherproof galvanized pipe | Round Steel for Outdoor Installations

Weatherproof galvanized pipe | Round Steel for Outdoor Installations

Couldn't load pickup availability

Weatherproof Galvanized Pipe | Round Steel for Outdoor Installations

Product Overview

Our galvanized steel water pipe solutions are engineered for superior corrosion resistance and structural integrity, ideal for outdoor plumbing, HVAC systems, and industrial applications. Designed to meet ASTM A53 and EN 10255 standards, these pipes excel in harsh environments, from coastal regions to chemical-heavy industrial zones. Compatible with schedule 40 galvanized pipe fittings, they ensure seamless installation and long-term reliability.

Technical Specifications

Certified for potable water systems, underground drainage, and high-pressure fluid transport.

| Parameter | Details |

|---|---|

| Material Grades | ASTM A53 (Galvanized Steel), ASTM A106 (Seamless), EN 10255 (Threaded) |

| Thickness | 0.5–12.7 mm (Customizable for galvanized steel water pipe and high-pressure systems) |

| Diameter | ½"–24" (15–600 mm) |

| Zinc Coating | 60–275 g/m² (Z60–Z275), hot-dip galvanized per ASTM A123 |

| Surface Treatment | Chromate passivation, anti-fingerprint finish, epoxy-coated variants |

| Hardness (HR30T) | 55–75 (Galvanized Steel) |

| MOQ | 3 tons |

Performance Attributes

Tensile Strength

Our schedule 40 galvanized pipe achieves tensile strengths of 330–480 MPa (ASTM A53), ensuring resilience against hydraulic pressures up to 1,200 psi. The zinc-iron alloy layer formed during galvanization enhances structural integrity, making these pipes suitable for underground installations and high-load industrial applications.

Bendability

Precision-rolled edges allow bending radii as low as 3× diameter without cracking. This is critical for complex layouts in water systems and compatibility with galvanized pipe connectors, ensuring leak-proof joints even in tight configurations.

Weight Calculation

- Galvanized Steel: 7.85 g/cm³ (e.g., 6" Schedule 40 pipe = 18.97 kg/m).

- Aluzinc Variants: 7.2 g/cm³ (e.g., 4" Aluzinc pipe = 10.2 kg/m).

Lightweight designs reduce transportation and installation costs by 15–30% compared to cast iron alternatives.

Anti-Corrosion Mechanism

The hot-dip galvanized coating creates a sacrificial zinc layer that oxidizes preferentially to steel, blocking moisture and chemical ingress. For galvanized steel water pipe in coastal areas, chromate passivation further enhances saltwater resistance, extending lifespan to 50–70 years. Stainless steel corrosion occurs due to chloride exposure, mechanical damage, or inadequate passivation, which compromises the chromium oxide layer.

Identification System

- Laser Marking: Batch codes (e.g., ASTM A53-Z275) and compliance labels (EN 10255).

- QR Tracking: Links to mill certificates, salt-spray test reports (1,000+ hours), and installation guidelines.

- Color Coding: Blue stripes denote potable water compliance; yellow indicates industrial use.

Manufacturing Excellence

Process Flow

- Material Sourcing: Prime-grade steel coils from ISO-certified mills.

- Galvanizing: Immersion in molten zinc at 450°C, with air-knife coating control for uniform thickness.

- Threading/Forming: CNC-machined threads for schedule 40 galvanized pipe fittings; hydraulic press for corrugated profiles.

- Quality Assurance: Eddy-current testing for coating uniformity; hydrostatic pressure tests up to 2,500 psi.

Customization Options

- Profiles: Smooth, corrugated, or helical designs for drainage and culverts.

- Coatings: Epoxy, PVC, or bitumen layers for extreme environments.

- Pre-Threaded Ends: Compatible with standard galvanized pipe connectors for rapid assembly.

Why Choose Our Stainless Steel Pipes?

- Superior Corrosion Resistance: Chromium-nickel alloys (304/316) resist pitting and crevice corrosion in chloride-rich environments, outperforming carbon steel by 5× lifespan.

- High-Temperature Resilience: Withstands temperatures up to 870°C (1,598°F), ideal for industrial steam systems.

- Hygienic Design: Smooth surfaces prevent bacterial growth, compliant with NSF/ANSI 61 for potable water.

- Sustainability: 100% recyclable with 60% recycled content; reduces maintenance costs by 40%.

- Global Compliance: Meets ASME B36.19, DIN 11850, and ISO 2037 standards for global applications.